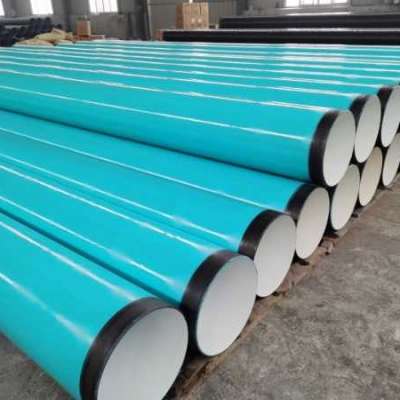

Epoxy coated steel pipes

Published By shenlong

Currently unavailable.

- Locationchina

- StatusCurrently unavailable.

- TypeNew

Epoxy coated steel pipe type

FBE coating, epoxy coating, plastic coating

Coating type: FBE, liquid epoxy,epoxy powder,epoxy coal tar

Standard: AWWA C210, C205, C203, C213, C215 etc.

Coating thickness: Epoxy:50μm-1000μm,FBE:100-500μm, as per customer requirement

Coated pipe OD: 34 -2540mm, Epoxy:50-1000μm

Epoxy coated steel pipe production process

First, Sand blasting after producing the bare steel pipes as per order requirement to remove oil and grease etc.thoroughly by high pressure fresh water cleaning. Abrasive blasting to minimum Sa 2½ (ISO 8501-1:2007)All damage of shop primer and contamination from storage and fabrication should be thoroughly cleaned prior to over coating.

Then processing coating by airless spray under suitable temperature to achieve maximum film build according to ordered coating thickness.

Epoxy coated steel pipe application

Widely used water treatment

Epoxy coated steel pipe capacity

Annual 100,000 tons

Epoxy coated steel pipe advantage

Competitive Price

Standard Complied Quality

Strict Quality Control

Considerate after-sale service

Fast delivery

Available EN10204 3.1 Certificate can be provided

Mill ISO certificate

Mill Product Catalog

Available Detailed Mill Company Profile

Available Mill Quality Manual

Available Mill ITP

Available Mill Past Project list

Epoxy coated steel pipe inspection

Hydrostatic testing, ultrasonic testing, eddy current testing, magnetic particle testing, impact testing, hardness testing, etc.

Epoxy coated steel pipe package and storage

Safe and Seaworthy packing suitable for export; As per customer’s requirement.

Epoxy coated steel pipe warranty

36 months

Epoxy coated steel pipe quality inspection:

1. Our factory has its own "experimental testing center".CNAS Laboratory Accreditation Certificate

2.Control quality strictly.The first pass is the quality inspection on the production line,The second pass is full inspection of the production quality .

3.We have got internationally recognized certificates, ISO, CE, LR,Philippine certificate,also support third-party testing,as SGS, BV, etc.