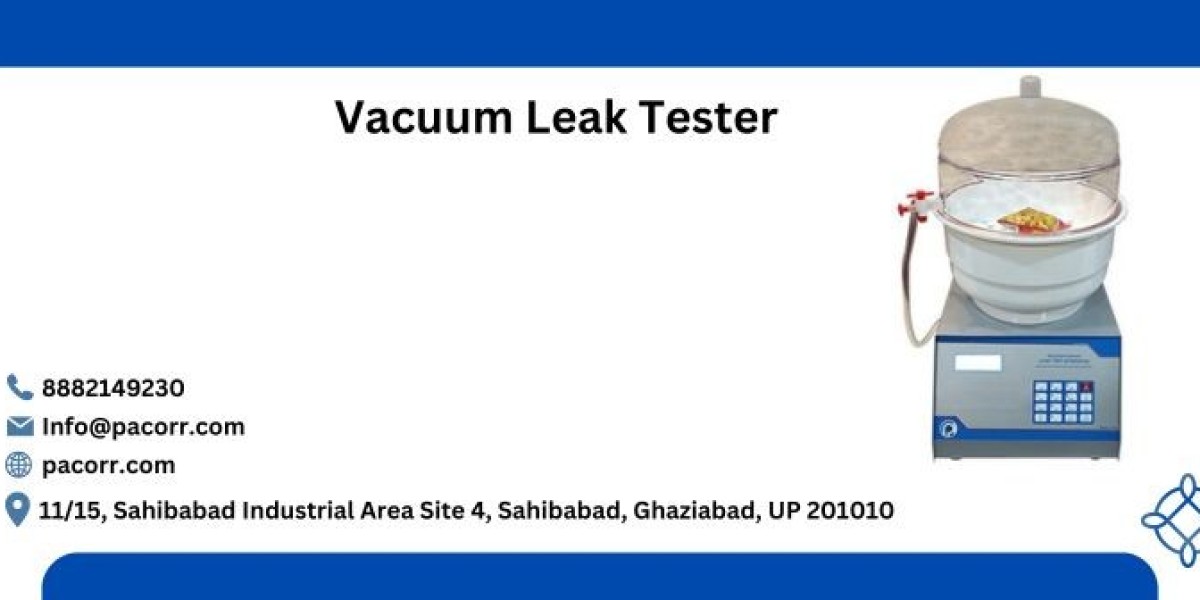

What is a Vacuum Leak Tester?

A Vacuum Leak Tester is a sophisticated device used to check for leaks in packaging without damaging the product. It works by creating a vacuum around the package, then monitoring the system for any loss of vacuum, which would indicate a leak. This method is crucial for ensuring the longevity and safety of the product inside the packaging, especially for food, pharmaceuticals, and chemicals, where contamination can lead to severe consequences.

Why is Vacuum Leak Testing Important?

Packaging integrity is paramount in preserving the quality, safety, and shelf life of products. A breach in packaging can lead to product spoilage, contamination, and ultimately, a loss of consumer trust and revenue. Vacuum Leak Testing allows manufacturers to identify and rectify these issues early in the production process, ensuring that each product meets strict quality standards before reaching the consumer.

How Vacuum Leak Testers Work

Vacuum Leak Testers generally operate by enclosing the test specimen in a chamber, from which air is evacuated using a vacuum pump. The system then monitors the chamber's pressure for any signs of a leak, often with sensitive pressure sensors capable of detecting even minute changes. Advanced testers may employ various methods to enhance detection sensitivity, such as tracer gases (e.g., helium) for more precise leak location identification.

Applications Across Industries

Food Packaging: Ensuring the integrity of vacuum-sealed foods to extend shelf life and prevent contamination.

Pharmaceuticals: Verifying the hermetic sealing of drug packages to maintain potency and prevent tampering.

Automotive: Testing components like fuel systems, air conditioning units, and brake systems for leaks to ensure safety and efficiency.

Aerospace: Ensuring the airtightness of spacecraft components, vital for crew safety and mission success.

Electronics: Checking the sealing of electronic components and batteries to prevent moisture ingress that can lead to failure.

Choosing the Right Vacuum Leak Tester

Selecting an appropriate Vacuum Leak Tester involves considering several factors:

Sensitivity: The tester's ability to detect small leaks.

Test Speed: How quickly the tester can perform a leak check.

Ease of Use: The user interface and any automation features.

Versatility: The ability to test different types of products or components.

Durability: Construction quality for longevity and reliability in various environments.

Conclusion

Vacuum Leak Testers are invaluable tools for maintaining high standards of quality and safety across numerous industries. By choosing the right tester for your needs and understanding its operation, you can significantly enhance your quality control processes, ensuring that products meet the stringent requirements necessary for consumer safety, regulatory compliance, and industry-specific standards.

Vacuum Leak Tester FAQ - Pacorr.com

What is a Vacuum Leak Tester?

A Vacuum Leak Tester is a precision instrument designed to check the sealing integrity of packaging materials. It detects leaks in packaging that cannot be seen by the naked eye, ensuring products are securely sealed and meet quality standards.

How does the Vacuum Leak Tester work?

The Vacuum Leak Tester works by creating a vacuum environment around the packaging being tested. Any decrease in vacuum level indicates a leak in the packaging material. The device measures this decrease to determine the integrity of the seal.

What types of packaging can be tested with the Vacuum Leak Tester?

This versatile device can test a wide range of packaging materials, including flexible packaging, bottles, cans, and blister packs. It's suitable for industries like food and beverage, pharmaceuticals, and consumer goods where packaging integrity is critical.

What features does the Vacuum Leak Tester on Pacorr.com offer?

The Vacuum Leak Tester available on Pacorr.com offers several advanced features:

Digital display for precise measurements.

Adjustable vacuum settings to simulate different conditions.

Durable construction for longevity and reliability.

User-friendly interface for ease of operation.

How can the Vacuum Leak Tester benefit my quality control process?

Incorporating the Vacuum Leak Tester into your quality control process can lead to significant benefits:

Ensures the integrity of your product packaging.

Reduces the risk of product spoilage or contamination.

Enhances customer satisfaction by delivering products in perfect condition.

Complies with industry standards and regulations regarding packaging.

Is the Vacuum Leak Tester difficult to operate?

No, the Vacuum Leak Tester is designed for ease of use. With a user-friendly interface and clear instructions, it requires minimal training to operate effectively. Technical support is also available for any questions that may arise.

Can the Vacuum Leak Tester be customized for specific testing requirements?

Yes, the Vacuum Leak Tester can be customized to meet specific testing requirements. Pacorr.com offers options for customization, including different sizes and vacuum levels, to accommodate a wide range of packaging materials and industry needs.

How can I purchase a Vacuum Leak Tester from Pacorr.com?

Purchasing a Vacuum Leak Tester from Pacorr.com is straightforward. Visit the website, navigate to the Vacuum Leak Tester product page, and follow the instructions for inquiry and purchase. Our sales team is also available to assist with any questions or custom requirements you may have.

Where can I find technical support for the Vacuum Leak Tester?

Technical support for the Vacuum Leak Tester is available directly through Pacorr.com. You can contact our support team via email, phone, or the contact form on our website for assistance with operation, maintenance, or troubleshooting.