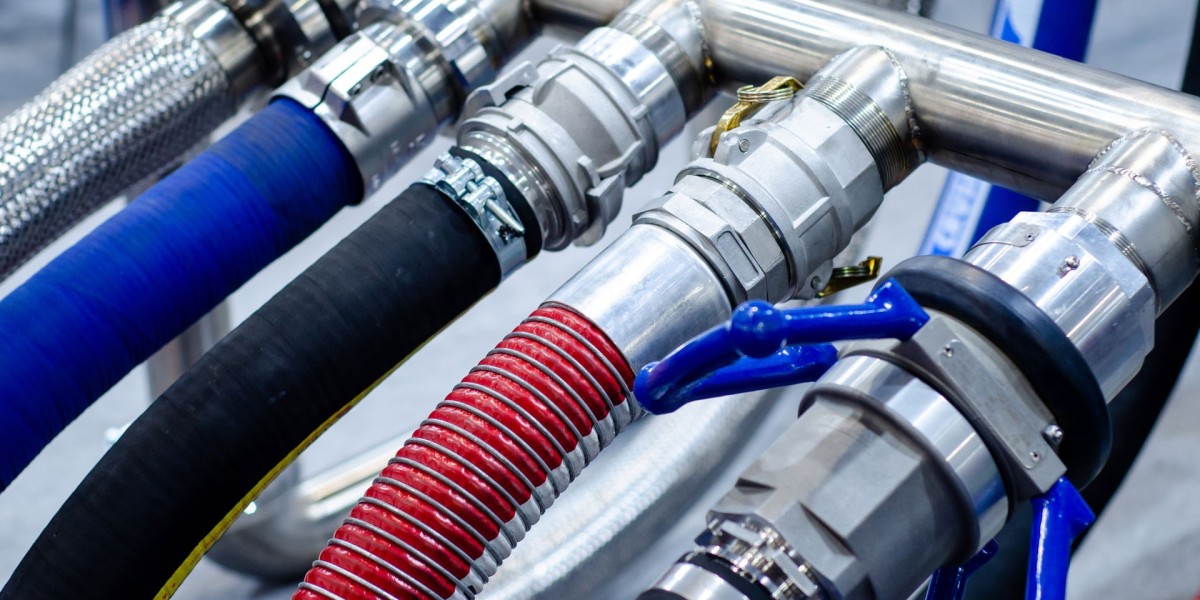

In the dynamic landscape of modern manufacturing, where efficiency and reliability are paramount, industrial hoses stand as unsung heroes, quietly facilitating the flow of materials and fluids critical to various processes. From transferring liquids and gases to conveying solids, these flexible conduits play a vital role in ensuring seamless operations across industries ranging from automotive and aerospace to pharmaceuticals and food processing.

The Backbone of Manufacturing Processes

At the heart of many manufacturing processes lies the need to move materials efficiently and safely. Industrial hoses serve as the backbone of these operations, enabling the transportation of liquids, gases, and granular materials with precision and reliability. Whether it's conveying chemicals in a petrochemical plant or transferring bulk materials in a mining facility, the right industrial hose can make all the difference in ensuring smooth operations.

Versatility and Adaptability

One of the most remarkable aspects of industrial hoses is their versatility. Designed to withstand a wide range of temperatures, pressures, and chemical exposures, these hoses can adapt to diverse environments and applications. From high-pressure hydraulic hoses used in heavy machinery to food-grade hoses ensuring sanitary transfer in the food and beverage industry, the versatility of industrial hoses makes them indispensable across various sectors.

Ensuring Safety and Compliance

In industries where the transfer of hazardous materials is commonplace, safety is paramount. Industrial hoses are engineered not only for efficiency but also for safety. Manufacturers adhere to stringent standards and regulations to ensure that hoses meet specific requirements for pressure ratings, material compatibility, and environmental conditions. Regular inspections and maintenance further ensure that hoses remain in optimal condition, minimizing the risk of leaks, spills, and accidents.

Innovations Driving Efficiency

As technology continues to advance, so too do Industrial Hoses and their associated components. Innovations such as lightweight materials, anti-static properties, and abrasion-resistant coatings enhance the performance and longevity of hoses, reducing downtime and maintenance costs for manufacturers. Moreover, the integration of smart sensors and monitoring systems enables real-time tracking of hose conditions, allowing for proactive maintenance and minimizing the risk of unexpected failures.

Environmental Considerations

In an era increasingly focused on sustainability and environmental responsibility, industrial hose manufacturers are also embracing eco-friendly practices. From using recyclable materials in hose construction to designing products with minimal environmental impact, the industry is striving to reduce its carbon footprint while maintaining the highest standards of performance and reliability.

Industrial hoses may not always be in the spotlight, but their role in modern manufacturing cannot be overstated. From facilitating the transfer of materials to ensuring safety and compliance, these flexible conduits form the lifelines of countless industries. As manufacturing processes evolve and demand for efficiency grows, industrial hoses will continue to adapt and innovate, remaining indispensable components of the industrial ecosystem.

Get more insights on Industrial Hose