Global Epoxy Composite Industry: Key Statistics and Insights in 2024-2032

Summary:

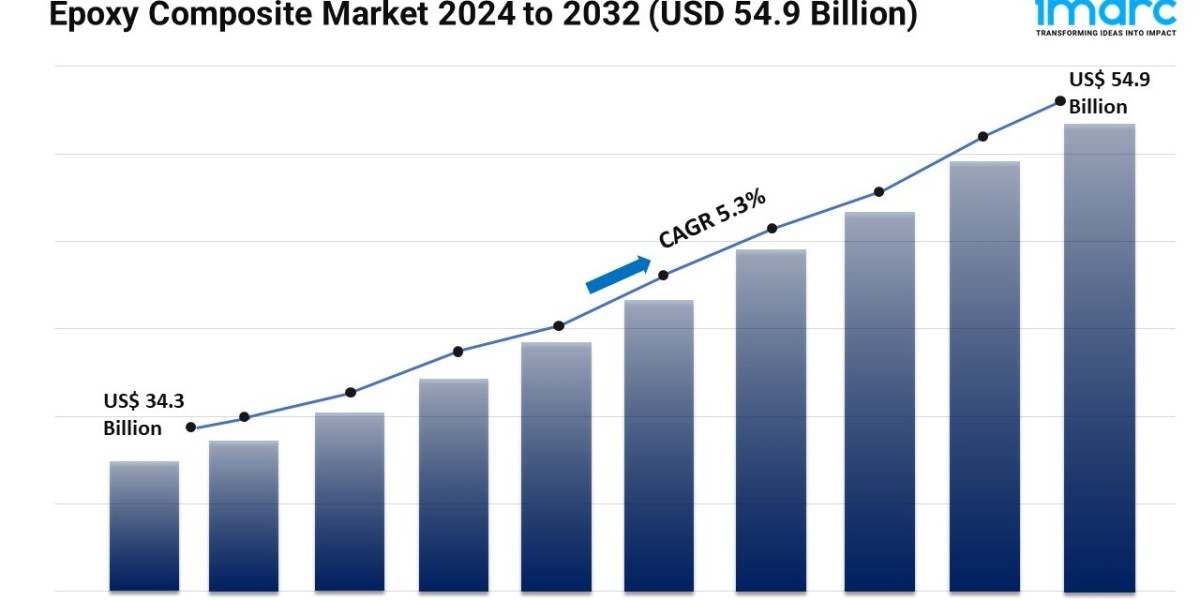

- The global epoxy composite market size reached US$ 34.3 Billion in 2023.

- The market is expected to reach USD 54.9 Billion by 2032, exhibiting a growth rate (CAGR) of 5.3% during 2024-2032.

- Asia Pacific leads the market, accounting for the largest epoxy composite market share.

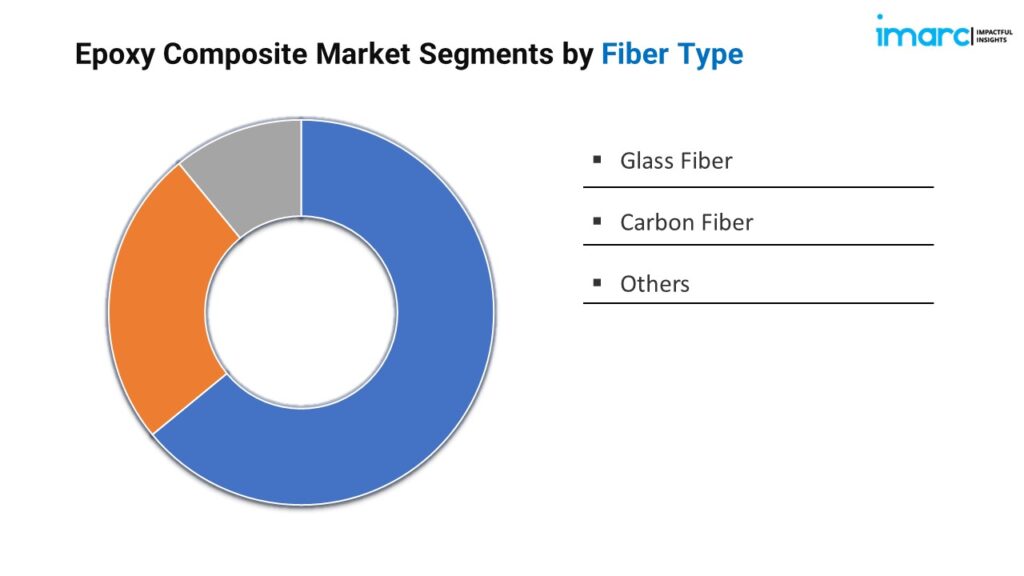

- Glass fiber accounts for the majority of the market share in the fiber type segment due to its excellent strength-to-weight ratio, which enhances the durability and performance of composite materials.

- On the basis of the manufacturing process, the market has been segmented into lay-up, compression moulding, resin injection, resin transfer moulding, filament winding, and pultrusion.

- Automotive remain a dominant segment in the market owing to the industry's focus on reducing emissions and enhancing vehicle design flexibility.

- The rising number of infrastructure development projects is a primary driver of the epoxy composite market.

- Ongoing research and development (RD) activities are reshaping the epoxy composite market.

Request for a sample copy of this report: https://www.imarcgroup.com/epoxy-composite-market/requestsample

Industry Trends and Drivers:

- Industrial applications:

The aerospace sector requires materials that are lightweight, strong, and durable. Epoxy composites meet these requirements and are used in the manufacturing of aircraft components, such as fuselages, wings, and interior parts. Their high strength-to-weight ratio helps reduce the overall weight of aircraft, enhancing fuel efficiency and performance. In the automotive industry, lightweighting is a key focus to improve fuel efficiency and reduce emissions. Epoxy composites find applications in vehicle components like body panels, chassis parts, and interior structures. Their use contributes to weight reduction while maintaining structural integrity, making them essential in the pursuit of greener and more efficient vehicles.

- Infrastructure development:

Infrastructure projects, such as bridges, tunnels, and buildings, require materials that can withstand the test of time. Epoxy composites are known for their exceptional durability and resistance to environmental factors, making them ideal for reinforcing and extending the lifespan of critical infrastructure. In regions with high humidity or coastal areas, corrosion is a major concern for infrastructure. Epoxy composites offers resistance to corrosion, even in harsh environments, which makes them a preferred choice for reinforcing concrete and steel structures, reducing maintenance costs, and ensuring the safety and longevity of infrastructure.

- Technological advancements:

Ongoing research and development (RD) activities are leading to innovations in epoxy composite materials. This includes the development of new resin formulations, reinforcement materials, and additives that enhance the performance, durability, and versatility of epoxy composites. Technological advancements are improving manufacturing processes for epoxy composites. Automation, precision molding, and 3D printing technologies enable the production of complex and customized components with high precision and consistency, reducing production costs and waste. Innovations, such as advanced manufacturing techniques, improved resin formulations, and enhanced fiber reinforcement technologies, enhance the efficiency and versatility of epoxy composites in various applications. Additionally, emerging technologies in automation and quality control are reducing production costs and increasing the adoption of epoxy composites across diverse industries.

Explore full report with table of contents: https://www.imarcgroup.com/epoxy-composite-market

Epoxy Composite Market Report Segmentation:

Breakup By Fiber Type:

- Glass Fiber

- Carbon Fiber

- Others

Glass fiber represents the largest segment due to its widespread use in the automotive, aerospace, and construction industries, where its high strength and cost-effectiveness make it a preferred reinforcement material for epoxy composites.

Breakup By Manufacturing Process:

- Lay-up

- Compression Moulding

- Resin Injection

- Resin Transfer Moulding

- Filament Winding

- Pultrusion

On the basis of the manufacturing process, the market has been segmented into lay-up, compression moulding, resin injection, resin transfer moulding, filament winding, and pultrusion.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific enjoys the leading position in the epoxy composite market on account of its robust industrial growth, particularly in automotive, construction, and aerospace sectors, along with increasing investments in infrastructure development.

Top Epoxy Composite Market Leaders:

The epoxy composite market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Arkema S.A

- Avient Corporation

- Axiom Materials Inc.

- Gurit

- Hexcel Corporation

- Huntsman Corporation LLC

- Mitsubishi Chemical Holdings Corporation

- SGL Carbon SE

- Solvay S.A

- Teijin Limited

- Toray Industries Inc.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145