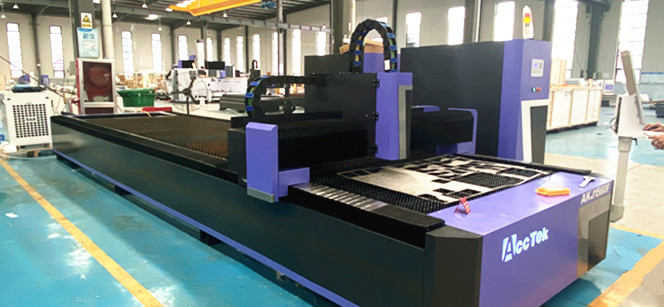

This is a customized fiber laser cutting machine, its worktable size is 1500×6000mm, which is specially customized for users to process longer metal plates. The video shows the process of 3000W fiber laser cutting machine AKJ1560F cutting stainless steel plate and carbon steel plate with different thickness. The following introduces its features to you.

AKJ1560 fiber laser cutting machine is equipped with 3000W IPG fiber laser. The biggest feature of IPG fiber laser cutting machine is that it can cut highly reflective metal materials, such as copper, aluminum and other metals. It is well known that highly reflective metals have low absorption rates for laser light. When an ordinary laser cutting machine cuts aluminum, the light that cannot be absorbed by the aluminum is reflected on the lens and then transmitted to the fiber laser. In this case, not only the lens loss is large, but also the damage to the laser is large, which will seriously shorten the life of the fiber laser. Therefore, if your shop needs to process large quantities of highly reflective metals, we recommend that you choose an IPG fiber laser cutting machine. Although its initial investment is more expensive than other types of metal laser cutting machine, IPG fiber laser cutting machines are more cost-effective in processing highly reflective materials in terms of long-term operating costs.

The 3000W fiber laser cutting machine is a very popular industrial metal processing equipment, which can cut carbon steel up to 20mm thick and stainless steel up to 10mm thick. For highly reflective metals, it can cut up to 8mm aluminum plate and 6mm copper plate, which can fully meet the processing of most industrial raw materials. The reason why the fiber laser cutting machine is so popular is because of its high efficiency and high precision. Using laser to cut metal is not only more efficient, but also has no burrs on the edge of the product after cutting, and can be put into use directly without secondary processing. Even when cutting very fine and small workpieces, the fiber laser cutting machine can still achieve higher machining accuracy. This is of higher significance for the production of precision instrument parts.

The 1560 fiber laser cutting machine adopts Raytools auto-focus laser cutting head, which can automatically find the best focal length instead of manual focusing, which is not only more efficient, but also avoids cutting errors caused by inaccurate manual focusing. Although a manual focus laser cutting head is several hundred dollars cheaper than an autofocus cutting head, it requires a very high level of skill for the laser machine operator. If there is an error in the manual focusing process, it will have an impact on the accuracy and production efficiency of the machine, especially for high-power metal laser cutting machines. Therefore, we recommend that when you choose a metal laser cutting machine above 1500W, it is best to equip it with an autofocus laser cutting head. The auto-focus laser head only needs to find the focal point for the first cut, and then when cutting again, the laser head will sense the thickness of the metal sheet and automatically adjust the height to find the appropriate focal length.

IPG fiber laser cutting machine is equipped with Japanese Yaskawa servo motor, which can ensure smooth operation when cutting metal plates even when the machine is running at high speed. Yaskawa absolute AC servo drive system greatly shortens the settling time, realizes high-speed acceleration and deceleration, and has a fast response speed. Servo systems are best suited for applications that require improved positioning accuracy and resolution. They run faster than stepper motors (usually a few thousand revolutions) and also provide more consistent torque across the speed range of the machine.

Because the 3000W IPG fiber laser cutting machine is a special customized size and needs to complete the processing of highly reflective materials, its high configuration determines its more expensive price. If your shop does not have the need to process highly reflective materials and special sizes, a standard 1530 fiber laser cutting machine can meet your needs, and its price starts from 17,000 US dollars. For more purchase suggestions for metal laser cutting machine, you can communicate online or leave us a message.