In the world of advanced manufacturing, high-precision composite printer molds play a crucial role in producing intricate and complex components. These molds are meticulously designed and constructed to ensure the highest level of accuracy and quality in the final product. In this blog post, we will delve into the detailed construction process of a high-precision composite printer mold, exploring the various steps involved and the technologies utilized.

1. Understanding the Design Requirements:

Before embarking on the construction of a high-precision composite printer mold, it is essential to thoroughly understand the design requirements. This involves analyzing the specifications, dimensions, and intricacies of the desired component. By gaining a comprehensive understanding of the design requirements, engineers can proceed with the construction process with precision and accuracy.

2. Material Selection:

The choice of materials for constructing a high-precision composite printer mold is critical. Factors such as thermal stability, dimensional stability, and durability must be considered. Common materials used in composite molds include epoxy resins, carbon fibers, and glass fibers. Each material possesses unique properties that contribute to the overall performance and longevity of the mold.

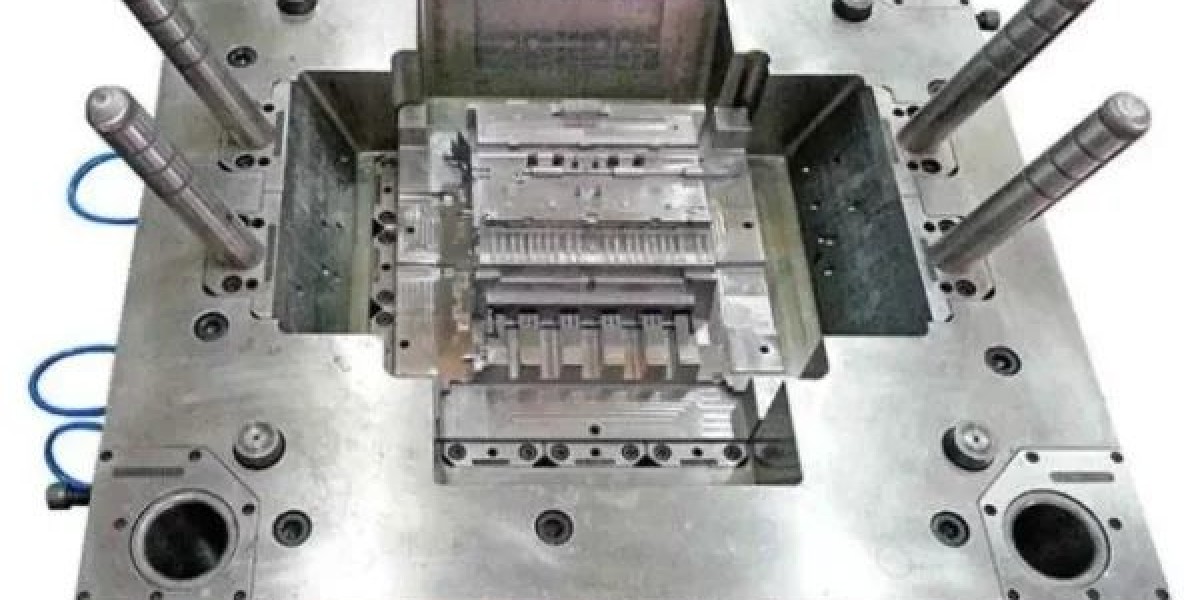

3. Mold Design and Fabrication:

Once the design requirements and materials are determined, the next step is mold design and fabrication. Computer-Aided Design (CAD) software is employed to create a detailed 3D model of the mold. This model serves as a blueprint for the fabrication process. Advanced machining techniques, such as CNC milling and electrical discharge machining (EDM), are utilized to precisely shape the mold components.

4. Surface Treatment and Coating:

To ensure optimal release properties and surface finish, the mold undergoes surface treatment and coating processes. Surface treatment techniques, such as sandblasting and chemical etching, are employed to enhance adhesion and remove any imperfections. Additionally, specialized coatings, such as PTFE (polytetrafluoroethylene) or silicone-based coatings, are applied to reduce friction and facilitate easy demolding.

5. Assembly and Integration:

The construction of a high-precision composite printer mold involves the assembly and integration of various components. This includes aligning and securing the mold inserts, ensuring proper cooling channels, and integrating ejector systems. Attention to detail and precision is crucial at this stage to guarantee the mold's functionality and longevity.

6. Quality Control and Testing:

Before the mold is put into production, it undergoes rigorous quality control and testing procedures. This involves inspecting the mold for dimensional accuracy, surface finish, and overall functionality. Advanced measurement techniques, such as coordinate measuring machines (CMM) and laser scanning, are utilized to verify the mold's compliance with design specifications.

7. Maintenance and Optimization:

Once the high-precision composite printer mold is in operation, regular maintenance and optimization are necessary to ensure its longevity and performance. This includes periodic cleaning, lubrication, and inspection of critical components. Additionally, any necessary adjustments or modifications are made to optimize the mold's performance and address any issues that may arise during production.

Conclusion:

The construction of a high-precision composite printer mold is a meticulous and intricate process that requires a deep understanding of design requirements, material selection, and advanced manufacturing techniques. By following a detailed construction process, engineers can create molds that deliver exceptional accuracy and quality in the production of complex components. With continuous maintenance and optimization, these molds can contribute to the advancement of advanced manufacturing technologies and the production of high-quality products.

Xuzhong is an excellent composite printer mold supplier. We will provide you with high-quality products and excellent services. Welcome to come for consultation at any time.

https://www.xuzhongmold.com/Detailed-construction-of-high-precision-composite-printer-mold.html