In the realm of modern manufacturing, precision and efficiency are paramount. Traditional welding methods have their merits, but as technology advances, so do the tools at our disposal. Enter the handheld laser welding machine – a game-changer in the world of welding. If you're looking to elevate your welding process to new heights, this comprehensive guide will walk you through everything you need to know about this innovative tool.

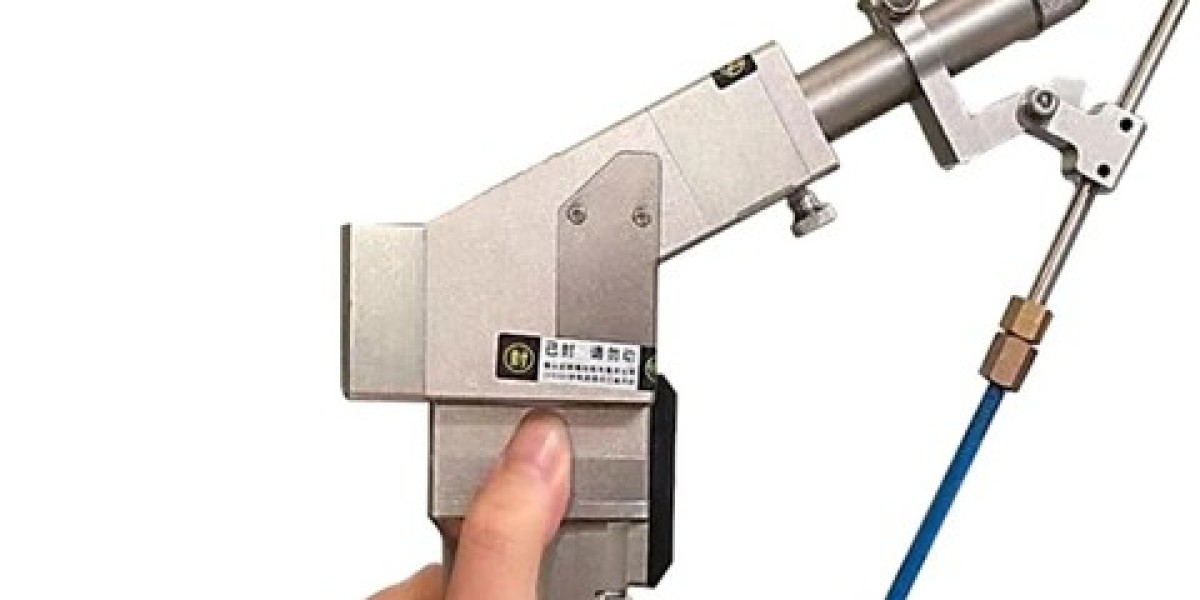

Understanding the Technology: Handheld laser welding machines utilize focused laser beams to join metal components with unparalleled precision. Unlike conventional welding techniques, such as MIG or TIG welding, laser welding offers significantly reduced heat input, minimal distortion, and superior weld quality.

Benefits Galore: The benefits of handheld laser welding machines are manifold. They enable faster welding speeds, increase productivity, and reduce material waste. Moreover, their versatility allows for welding various materials, including stainless steel, aluminum, and titanium, with ease.

Application Versatility: From automotive and aerospace industries to electronics and jewelry manufacturing, handheld laser welding machines find applications across diverse sectors. Their ability to perform intricate welds in hard-to-reach areas makes them indispensable in modern production processes.

Efficiency Redefined: Say goodbye to time-consuming setup and post-weld cleanup. Handheld laser welding machines streamline the welding process, requiring minimal preparation and leaving behind clean, precise welds. This translates to significant time and cost savings for businesses.

Factors to Consider: When investing in a handheld laser welding machine, several factors come into play. Considerations such as power output, beam quality, and ergonomic design are crucial for selecting the right machine to suit your specific needs.

Safety Measures: While handheld laser welding machines offer numerous advantages, safety should always remain a top priority. Proper training, the use of protective gear, and adherence to safety protocols are imperative to prevent accidents and ensure a secure working environment.

Future Prospects: As technology continues to evolve, so will handheld laser welding machines. Innovations such as improved beam delivery systems, enhanced automation features, and integration with IoT are poised to further revolutionize the welding industry.

In conclusion, the handheld laser welding machine represents a paradigm shift in welding technology. Its precision, efficiency, and versatility make it a must-have tool for manufacturers striving to stay ahead in today's competitive market landscape. By embracing this cutting-edge technology, businesses can unlock new levels of productivity and quality in their welding processes. So why wait? Take the leap and embrace the future of welding with LASERCHINA's handheld laser welding machines.