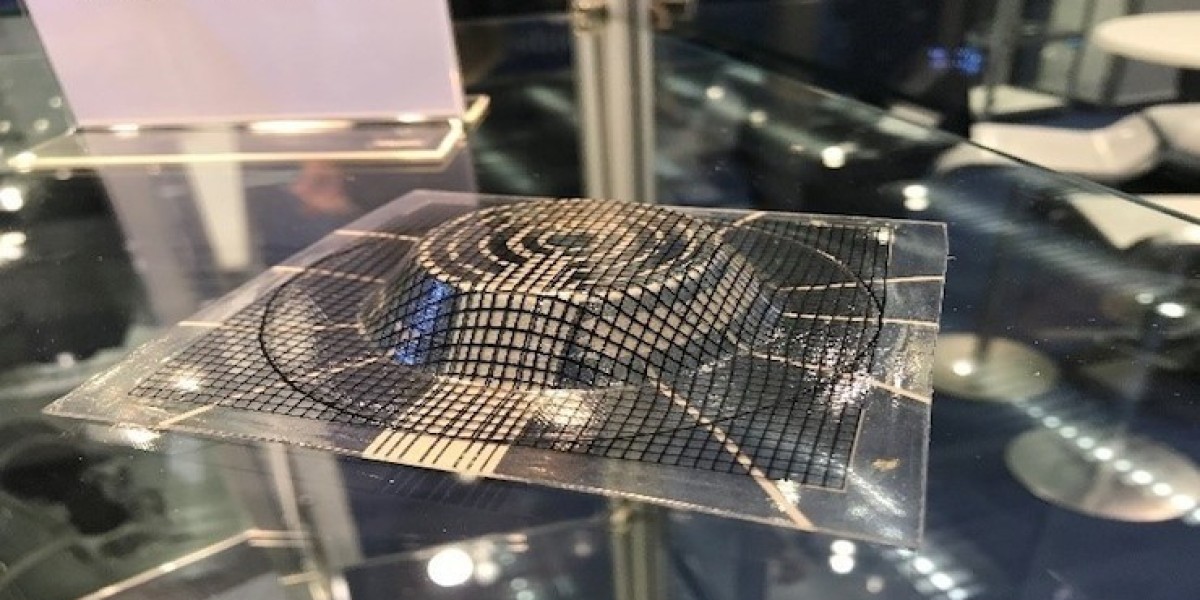

A completely new universe of functionally improved goods and interfaces is made feasible by In-Mold Electronics.

These Smart Molded Parts of the future are being designed and produced to take full advantage of all the advantages and benefits that IME offers, including the potential to add ornamental graphics, lighting, and a plethora of other capabilities.

In recent years, the In Mold Electronics (IME) market has witnessed significant growth, driven by technological advancements and increasing demand for lightweight, durable, and aesthetically pleasing electronic devices. IME involves the integration of electronic functionalities into molded plastic parts during the manufacturing process, eliminating the need for traditional assembly methods. This innovative approach has garnered attention across various industries, revolutionizing the way electronic devices are designed and manufactured.

The In Mold Electronics Market is estimated to be valued at US$ 228.73 Mn in 2024 and is expected to reach US$ 1,248.47 Mn by 2031, exhibiting a compound annual growth rate (CAGR) of 27.4% from 2024 to 2031.

Market Drivers

Several factors are driving the growth of IME Market. Firstly, the consumer electronics industry's relentless pursuit of thinner, lighter, and more ergonomic designs has spurred the adoption of IME technology. Manufacturers are leveraging IME to create seamless and integrated electronic interfaces on curved surfaces, such as smartphone casings and automotive dashboards. Additionally, the automotive sector's focus on vehicle electrification and the development of smart interiors has fueled the demand for IME solutions, enabling the integration of touch controls, lighting, and sensor functionalities directly into automotive panels.

Key Takeaways

As the IME market continues to evolve, key takeaways emerge for stakeholders. One notable trend is the convergence of IME with additive manufacturing techniques like 3D printing, enabling the rapid prototyping and customization of electronic devices. Moreover, advancements in materials science are expanding the possibilities for IME applications, with conductive inks and flexible substrates enabling the creation of conformable and stretchable electronic circuits.

PEST Analysis

A PEST analysis provides valuable insights into the external factors shaping the IME market's landscape. Politically, supportive government policies and initiatives promoting innovation and technology adoption can create conducive environments for IME companies to thrive. Economically, the growing middle-class population and rising disposable incomes in emerging markets present lucrative opportunities for IME product penetration. Socially, the increasing focus on sustainability and environmental consciousness is driving demand for eco-friendly IME solutions. Technologically, ongoing advancements in materials science, printing technologies, and miniaturization are accelerating the development and adoption of IME applications.

SWOT Analysis

A SWOT analysis helps to assess the internal strengths and weaknesses of IME companies, along with external opportunities and threats in the market. Strengths include IME's ability to streamline manufacturing processes, reduce assembly costs, and enhance product aesthetics. Weaknesses may arise from the challenges associated with scaling up production and ensuring consistent quality control. Opportunities lie in expanding into new industry verticals, such as healthcare and aerospace, where IME's benefits can be leveraged. Threats include potential competition from traditional electronic assembly methods and the risk of technological obsolescence.

Segment Analysis

The IME market can be segmented based on application, substrate type, and end-user industry. In terms of application, key segments include touch sensors, lighting systems, printed heaters, and capacitive switches. Substrate types range from rigid substrates like polycarbonate to flexible substrates such as polyethylene terephthalate (PET) and polyimide. Major end-user industries driving IME adoption include consumer electronics, automotive, healthcare, and aerospace.

Geographical Region

The adoption of IME technology varies across geographical regions, influenced by factors such as technological infrastructure, regulatory environment, and market demand. North America and Europe lead the IME market, driven by the presence of key players, strong R&D capabilities, and high demand for premium electronic products. Asia-Pacific is emerging as a significant growth market, fueled by rapid industrialization, urbanization, and increasing investments in automotive and consumer electronics manufacturing. Countries like China, Japan, and South Korea are at the forefront of IME innovation and adoption, supported by robust supply chains and a skilled workforce.