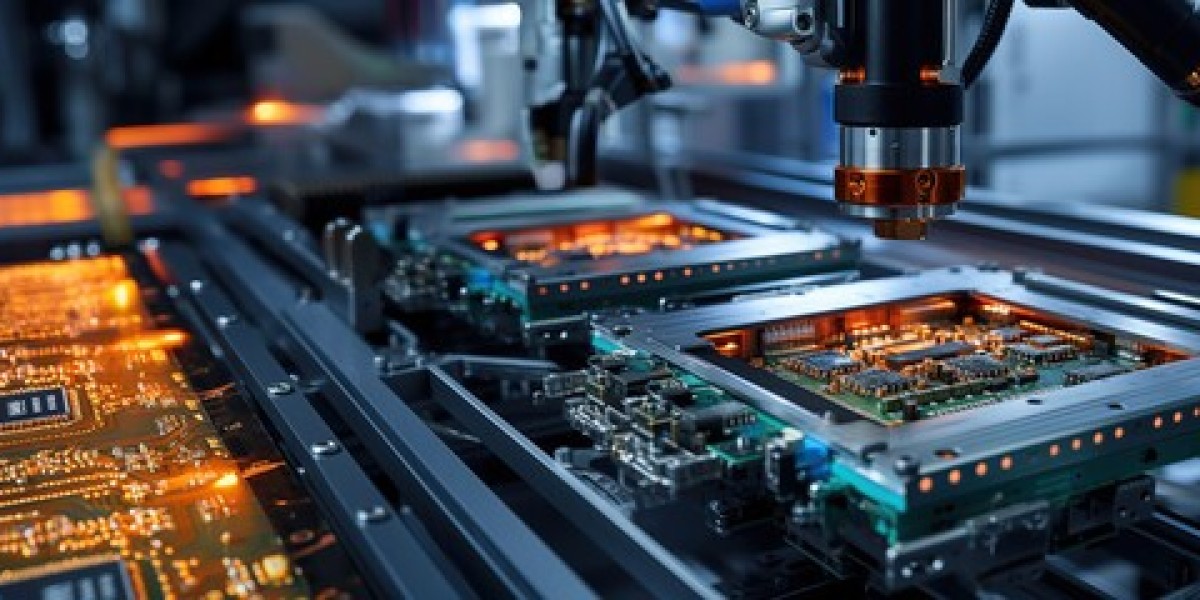

Pharmaceutical Industry Automation: The Role of Industrial Robotics

Industrial robotics has revolutionized various sectors, and the pharmaceutical industry is no exception. With the advancement of technology, the integration of robotics has become increasingly prevalent, transforming traditional pharmaceutical processes and driving innovation. In this article, we delve into the significance of industrial robotics in the pharmaceutical sector, exploring its evolution, benefits, applications, challenges, and future trends.

Introduction

In today's rapidly evolving pharmaceutical landscape, automation plays a pivotal role in enhancing efficiency, precision, and safety across the entire drug development and manufacturing process. Pharmaceutical industry automation encompasses the use of advanced technologies, including robotics, to streamline operations, reduce human intervention, and ensure consistent quality standards.

The Evolution of Industrial Robotics in Pharmaceuticals

The adoption of industrial robotics in the pharmaceutical industry has been a gradual process, marked by significant milestones and technological advancements. Initially, robotics were primarily used in repetitive tasks such as pick-and-place operations. However, with time, their capabilities expanded, enabling more complex functions such as automated drug synthesis and compound screening.

Benefits of Industrial Robotics in Pharmaceuticals

The integration of industrial robotics offers a myriad of benefits to pharmaceutical manufacturers. Firstly, it enhances efficiency and productivity by automating time-consuming tasks, allowing companies to accelerate their production processes and meet growing market demands. Additionally, robotics ensure heightened accuracy and precision in critical operations such as dispensing and compounding, minimizing the risk of errors and contamination.

Furthermore, industrial robotics contribute to enhanced safety for workers by eliminating the need for manual handling of hazardous substances and repetitive motions that may lead to ergonomic injuries. By automating high-risk tasks, robots help create a safer working environment while improving overall operational efficiency.

Applications of Industrial Robotics in Pharmaceuticals

Industrial robotics find extensive applications throughout the pharmaceutical supply chain, from drug development to distribution. In manufacturing facilities, robots are utilized for automated compounding, blending, and granulation, ensuring consistent product quality and dosage accuracy. Moreover, robotic arms equipped with advanced sensors and vision systems enable precise packaging and labeling of pharmaceutical products, reducing packaging errors and minimizing waste.

Quality control and inspection are another critical area where industrial robotics play a crucial role. Robots equipped with sophisticated sensors and imaging technology can perform thorough quality checks, detecting defects and deviations in real-time, thus maintaining compliance with stringent regulatory standards.

Challenges and Limitations

Despite the numerous benefits of industrial robotics, their implementation in the pharmaceutical industry poses certain challenges. One major obstacle is the high initial costs associated with acquiring and integrating robotic systems into existing infrastructure. Moreover, ensuring regulatory compliance and validation of automated processes requires meticulous documentation and testing, which can be time-consuming and resource-intensive.

Additionally, the complexity of pharmaceutical manufacturing processes and the variability of drug formulations present challenges in designing robotic solutions that are versatile and adaptable to diverse requirements. Overcoming these challenges requires close collaboration between manufacturers, regulatory agencies, and technology providers to develop robust and scalable automation solutions.

Future Trends

Looking ahead, the future of industrial robotics in the pharmaceutical industry appears promising, with ongoing advancements in technology driving innovation and expanding the scope of automation. Emerging trends include the integration of artificial intelligence (AI) and machine learning algorithms to enhance the capabilities of robotic systems, enabling autonomous decision-making and adaptive control.

Furthermore, we anticipate a proliferation of robotic applications in areas such as personalized medicine, where customized drug formulations and dosage forms are tailored to individual patient needs. Moreover, the rise of collaborative robots (cobots) that can work alongside human operators in shared workspaces is expected to revolutionize pharmaceutical manufacturing, enabling flexible and agile production processes.

Conclusion

In conclusion, industrial robotics play a vital role in shaping the future of the pharmaceutical industry, offering transformative solutions to address the evolving challenges and demands of modern drug development and manufacturing. By harnessing the power of automation, pharmaceutical companies can achieve higher levels of efficiency, quality, and safety, ultimately driving innovation and improving patient outcomes.

FAQs

What types of tasks can industrial robots perform in pharmaceutical manufacturing?

- Industrial robots in pharmaceutical manufacturing can perform a wide range of tasks, including compounding, blending, packaging, labeling, and quality control.

How do industrial robots contribute to workplace safety in pharmaceutical facilities?

- By automating hazardous and repetitive tasks, industrial robots help reduce the risk of workplace injuries and exposure to harmful substances, creating a safer working environment for employees.

What are some of the challenges associated with implementing industrial robotics in the pharmaceutical industry?

- Challenges include high initial costs, regulatory compliance, and the complexity of pharmaceutical manufacturing processes, which require careful planning and coordination to overcome.

What role does artificial intelligence play in enhancing the capabilities of industrial robots in pharmaceuticals?

- Artificial intelligence enables robots to analyze data, make informed decisions, and adapt to changing conditions, thereby enhancing their efficiency, flexibility, and autonomy in pharmaceutical applications.

What are the future prospects for industrial robotics in the pharmaceutical sector?

- The future of industrial robotics in pharmaceuticals looks promising, with advancements in technology driving innovation and expanding the scope of automation, leading to more agile, efficient, and personalized manufacturing processes.