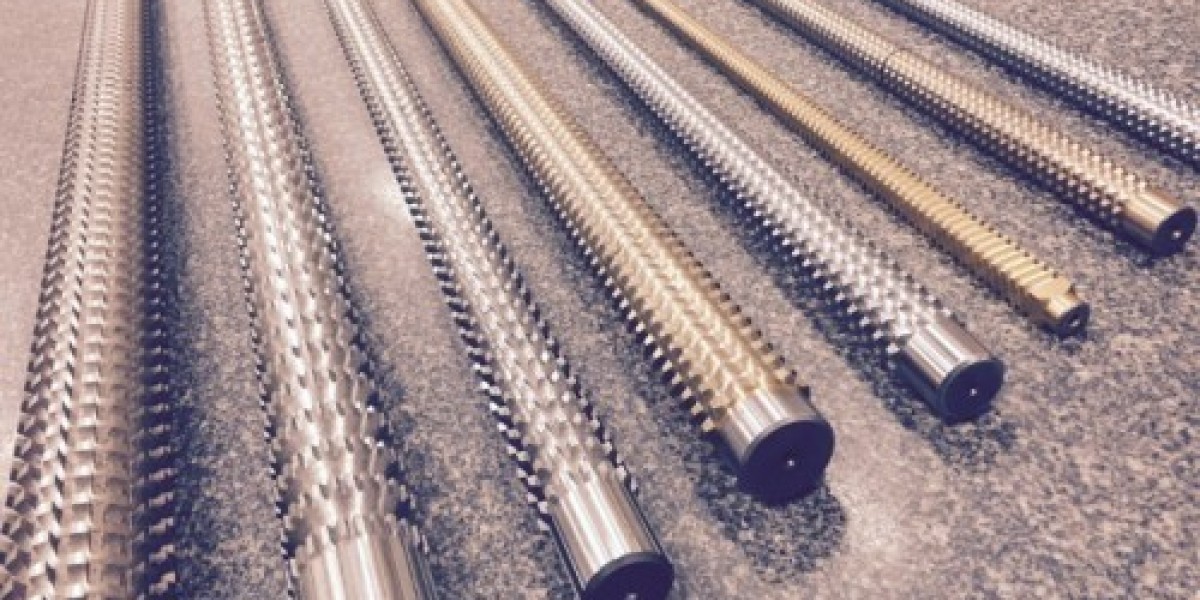

They are cutting tools used for shaping workpieces through linear cutting actions. They have multiple cutting teeth arranged in a row that progressively scrape away material from the workpiece to deliver a smooth ultra-precision finish. Some common examples where they are used include gear cutting, keyway cutting, spline shaping, etc. Broaching allows for fast, economical and accurate mass production of components with holes, slots and complex internal or external shapes.

Types

There are different types of broaching tools available depending on the tool geometry, number of cutting edges and intended metalworking application:

Straight Sided Broaching Tools

Straight sided they have cutting teeth arranged in a straight line. They are used for basic linear broaching operations to cut slots, flat surfaces and external forms. Each tooth performs the same cutting action to progressively plunge into the work material. Straight pull broaches are commonly used in the Broaching Tools of splines, keyways and other simple operations.

Form Broaching Tools

They have an irregular non-linear tooth geometry allowing them to cut complex contoured internal or external forms. The cutting teeth are specially profiled to match the intended profile of the workpiece. Serpentine form broaches have an S-shaped profile while spiral form broaches have helical cutting edges. They are mainly used for shaping gear teeth, cam profiles and intricate contours with tight tolerances.

Insert Broaching Tools

They have feature removable and replaceable cutting inserts instead of a solid body construction. This allows easy replacement of worn inserts, providing a more cost-effective solution for high production volumes. The inserts come in various geometries and are securely held in place using clamping bolts. Inserting it offer improved chip evacuation for tough materials like hardened steel.

Pull Broaching Tools

They are designed to cut in a unidirectional pull stroke motion. The cutting teeth each remove a small bite of material with each pull stroke pass. Multiple tooth broaches have intermediate lands between teeth to break chips into smaller pieces. Pull broaches are commonly used for profile cutting and flat bottom holes.

Push Broaching Tools

Compared to pull broaching, they cut during the return push stroke motion. This pushing action allows for more aggressive metal removal but can hamper chip evacuation. Push broaches are suitable for deep slotting operations along their longitudinal axis in softer metals.

Applications

Broaching is widely used in the manufacturing industry for mass-producing components with tight tolerances. Here are some of the common applications of these tools:

Gear Cutting

They play a vital role in gear cutting operations. Form broaches with matching gear profiles are used to cut teeth on external and internal spur, helical and worms gears with micron level precision. Broaching allows cost-effective multi-stage gear cutting.

Spline and Keyway Cutting

Cutting internal and external splines and keyways is one of the most prevalent applications of broaching. Straight sided broaches produce splines and slots with superior accuracy, finish and consistency required in power transmission applications.

Shaping of Cam and Crank profiles

Complex contoured cam and crank profiles for engines and machinery are efficiently shaped using specially profiled serpentine or spiral form broaching tools matched to the design. Close tolerances are achieved economically.

Drilling and Reaming

Broaching can replace multiple internal drilling and reaming steps by performing internal sizing, finishing and deburring in a single pass. Complex deep hole geometries and shapes are attainable.

Gun components

They are used extensively in the fabrication of small precision components in firearms such as action parts, triggers, firing pins etc. due to their capability for micro-finishing.

Benefits of Broaching

Some of the key benefits that make broaching an effective cold working operation include:

- High precision and consistency in component dimensions and geometry. Tolerances of ±0.002 mm are achievable.

- Superior surface finish Rz 2-6 μm of broached parts reduces the need for additional finishing processes.

- Fast metal removal rates for high productivity compared to other single point cutting methods.

- Multi-stage broaching uses one setup for complex profiles with fewer handling steps.

- Minimal distortion of workpiece due to controlled chip removal without high cutting temperatures.

- Broached components meet tightened industrial specifications for interchangeability.

These tools have made an indispensable contribution towards high-volume machining needs in manufacturing sectors. Their ability to produce parts with intricately machined contours, holes and slots at precise tolerances has enhanced productivity over conventional techniques. Continuous innovations in broaching technology is expanding the range of profiles and applications.

Get more insights on Broaching Tools