Aluminium alloys are widely recognized for their versatility, strength, and light weight, making them indispensable in various industries ranging from aerospace to automotive and marine applications. Among the myriad of aluminium alloys available, Aluminium Alloy 5754 stands out for its excellent corrosion resistance, weldability, and formability, making it a preferred choice in many critical applications.

Understanding Aluminium Alloy 5754

Aluminium Alloy 5754 belongs to the wrought aluminium-magnesium family (5xxx series) and is characterized by its high strength and excellent corrosion resistance. It is known for its versatility and is used extensively in industries where durability and lightweight properties are crucial. The key properties of Aluminium Alloy 5754 include:

Corrosion Resistance: It exhibits outstanding resistance to corrosion in marine and industrial environments, making it suitable for applications exposed to harsh conditions.

Strength: Alloy 5754 offers good strength, especially in the hardened state, making it suitable for structural components and panels where strength-to-weight ratio is critical.

Formability: It is highly formable and can be easily shaped into complex forms using various techniques such as rolling, bending, and deep drawing.

Weldability: The alloy can be welded using various methods including arc and resistance welding, without compromising its mechanical properties significantly.

Applications of Aluminium Alloy 5754 Sheet Plate

The versatility and robust properties of Aluminium Alloy 5754 make it indispensable in a wide range of applications:

Marine Industry: Due to its excellent corrosion resistance, Alloy 5754 is extensively used in marine environments for building ship structures, boat hulls, and other components exposed to seawater.

Automotive Sector: In the automotive industry, the alloy finds application in vehicle body panels, flooring, and structural components where lightweight and high strength are essential for fuel efficiency and performance.

Construction: It is used in construction for roofing, cladding, and structural components where durability and resistance to atmospheric corrosion are required.

Aerospace: Alloy 5754 is utilized in aircraft structures, fuselage panels, and interior fittings due to its lightweight nature and ability to withstand high stress conditions.

General Engineering: It finds use in various engineering applications such as pressure vessels, storage tanks, and welded structures where a combination of strength and corrosion resistance is needed.

Fabrication and Processing

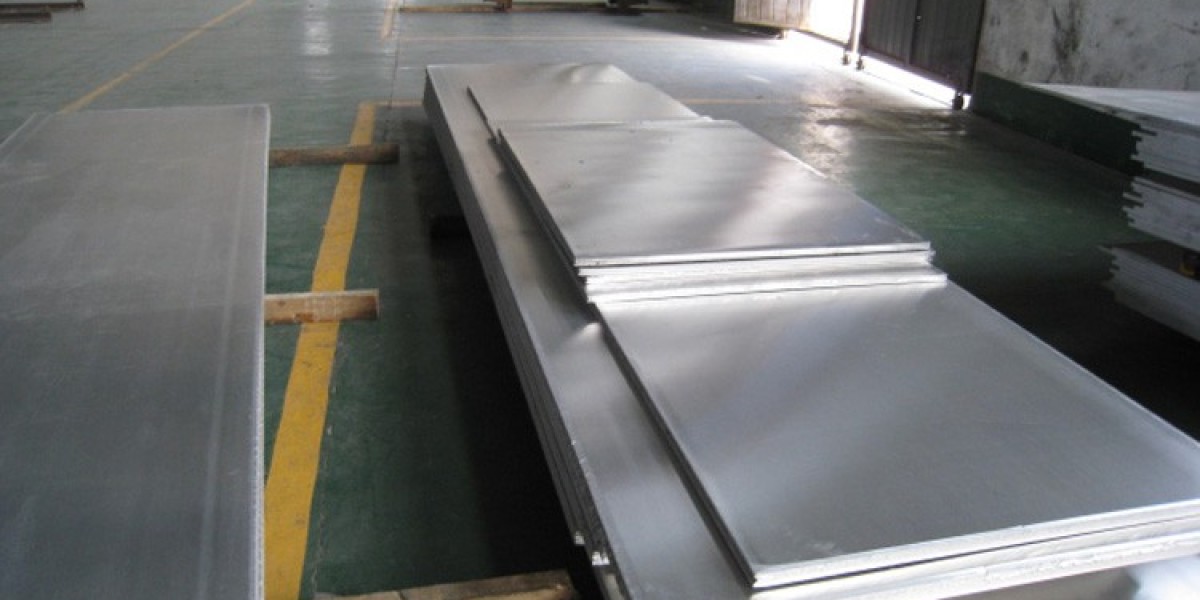

Aluminium Alloy 5754 Sheet Plate is manufactured through a series of processes including casting, rolling, and finishing operations:

Casting: The alloy is initially cast into ingots of specific compositions.

Hot Rolling: The ingots are hot rolled into thinner gauge sheets or plates to achieve the desired dimensions and mechanical properties.

Cold Rolling: Further cold rolling may be performed to achieve tighter tolerances and improved surface finish.

Surface Treatment: The sheets or plates may undergo surface treatments such as anodizing or painting to enhance corrosion resistance or for decorative purposes.

Conclusion

Aluminium Alloy 5754 Sheet Plate exemplifies the remarkable capabilities of aluminium alloys in modern industrial applications. Its combination of strength, corrosion resistance, and formability makes it a go-to material in diverse sectors including automotive, aerospace, marine, and construction. As technology continues to advance, the demand for lightweight, durable materials like Alloy 5754 is expected to grow, further cementing its importance in shaping the future of various industries.

Whether you're designing the next generation of aircraft or seeking materials for marine applications, Aluminium Alloy 5754 stands ready as a reliable and efficient choice, embodying the best qualities of modern engineering materials.

In conclusion, Alloy 5754 represents not just a material, but a testament to the ingenuity and versatility of aluminium alloys in meeting the challenges of contemporary industry requirements.