The rapid expansion of wind energy as a viable source of renewable power has brought the operation and maintenance (O&M) of wind turbines into sharp focus. The primary goal of O&M activities is to ensure that wind turbines operate at peak efficiency, generating the maximum possible energy output while minimizing downtime and maintenance costs. Given the significant investment involved in wind energy projects, effective O&M practices are essential for protecting assets, optimizing performance, and ensuring the long-term viability of wind farms.

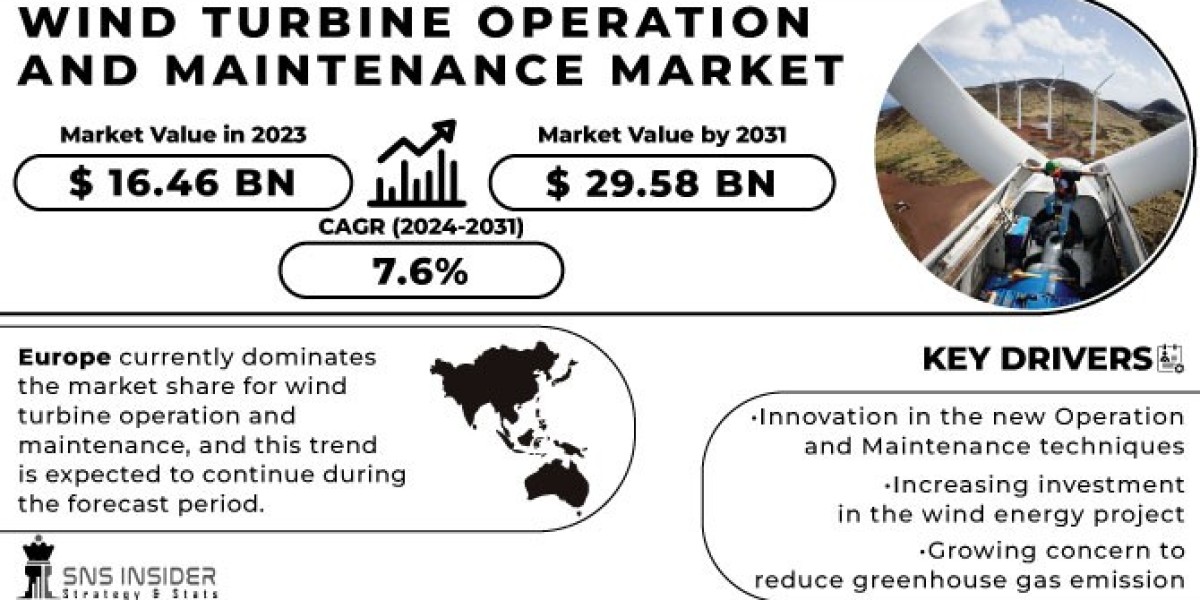

Wind turbines are subject to various operational stresses, including mechanical wear, environmental factors, and grid integration challenges. Proper operation and maintenance are crucial for addressing these issues, preventing failures, and ensuring that turbines continue to produce energy efficiently throughout their operational life. The Wind Turbine Operation and Maintenance Market size was valued at USD 16.46 billion in 2023 and is expected to grow to USD 29.58 billion by 2031 and grow at a CAGR of 7.6% over the forecast period of 2024-2031.

Key Aspects of Wind Turbine Operation

Operating wind turbines efficiently requires a combination of monitoring, control, and management strategies designed to optimize energy production. Some of the critical aspects of wind turbine operation include:

Real-Time Monitoring and Diagnostics: Modern wind turbines are equipped with advanced sensors that continuously monitor various parameters such as wind speed, rotor speed, power output, temperature, and vibration levels. This data is transmitted to a central control system where it is analyzed in real-time. Any deviations from normal operating conditions can be quickly identified, allowing for timely interventions to prevent potential failures.

Adaptive Control Systems: The control systems of a wind turbine are responsible for adjusting the blade pitch, rotor speed, and turbine orientation to optimize energy capture. Adaptive control algorithms can adjust these parameters based on real-time wind conditions, ensuring that the turbine operates within its optimal performance range. This not only maximizes energy output but also reduces mechanical stress on the turbine components, extending their lifespan.

Grid Connection and Stability: Wind turbines must be properly integrated into the electrical grid to ensure a stable and reliable supply of electricity. This involves managing the variability of wind energy, synchronizing with grid frequency, and maintaining voltage levels. Effective grid integration strategies are essential for minimizing the impact of wind energy variability on the overall power system.

Environmental Monitoring: Wind turbines operate in diverse and often harsh environments, from coastal areas to high-altitude locations. Environmental factors such as temperature extremes, humidity, and saltwater exposure can affect the performance and durability of turbine components. Continuous environmental monitoring allows operators to adjust maintenance schedules and implement protective measures to mitigate these effects.

Maintenance Practices for Wind Turbines

Maintenance of wind turbines involves a combination of scheduled preventive actions and corrective interventions. The goal is to minimize unplanned downtime, reduce maintenance costs, and ensure that turbines continue to operate efficiently. Key maintenance practices include:

Scheduled Preventive Maintenance: Preventive maintenance involves regular inspections, servicing, and replacement of components according to a predefined schedule. This helps to prevent unexpected failures and extend the operational life of the turbine. Typical preventive maintenance tasks include checking the condition of blades, bearings, and gearboxes, as well as ensuring that electrical systems are functioning properly.

Condition-Based Maintenance: Condition-based maintenance relies on continuous monitoring of turbine performance data to determine the optimal timing for maintenance activities. By analyzing trends in vibration levels, temperature, and other parameters, operators can predict when a component is likely to fail and perform maintenance just before that happens. This approach helps to reduce unnecessary maintenance, lower costs, and prevent catastrophic failures.

Remote Monitoring and Diagnostics: The use of remote monitoring and diagnostics has become increasingly important in wind turbine maintenance. By leveraging digital technologies and the Internet of Things (IoT), operators can monitor the condition of turbines in real-time, regardless of their location. This allows for early detection of issues, enabling operators to take corrective action before a minor problem escalates into a major failure.

Component Replacement and Upgrades: Over time, certain turbine components, such as bearings, gearboxes, and blades, may need to be replaced due to wear and tear. In some cases, upgrading components with more advanced versions can improve turbine performance and efficiency. For example, replacing older blades with newer, more aerodynamically efficient designs can increase energy capture and reduce mechanical stress on the turbine.

Safety Inspections: Ensuring the safety of wind turbine operations is a critical aspect of maintenance. Regular safety inspections are necessary to identify any potential hazards, such as loose components, electrical faults, or structural damage. Addressing these issues promptly helps to prevent accidents and ensures the safe operation of the wind farm.

Emerging Trends in Wind Turbine O&M

The wind energy industry is rapidly evolving, and new trends in operation and maintenance are emerging to address the challenges of modern wind farms. Some of these trends include:

Predictive Analytics and AI: Predictive analytics, powered by artificial intelligence (AI), is becoming a cornerstone of wind turbine maintenance. By analyzing vast amounts of data collected from turbines, AI algorithms can predict potential failures with high accuracy, allowing operators to take preemptive action. This reduces downtime, lowers maintenance costs, and extends the life of turbine components.

Drones and Robotics: The use of drones and robotics for inspections and maintenance is gaining traction in the wind energy sector. Drones can quickly and safely inspect turbine blades and other hard-to-reach areas, capturing high-resolution images and thermal data. Robotics, on the other hand, can perform tasks such as cleaning, lubrication, and even component replacement, reducing the need for manual interventions.

Offshore Wind Farm Maintenance: As the number of offshore wind farms increases, specialized maintenance strategies are being developed to address the unique challenges of the marine environment. This includes the use of autonomous vessels for transport and logistics, as well as corrosion-resistant materials and coatings to protect turbine components from saltwater exposure.

Sustainability and Lifecycle Management: The focus on sustainability is driving the adoption of lifecycle management practices in wind turbine O&M. This involves considering the entire lifecycle of the turbine, from design and manufacturing to operation and decommissioning, to minimize environmental impact and maximize resource efficiency. Recyclable materials, efficient energy use, and responsible waste management are key aspects of this approach.

Conclusion

Wind turbine operation and maintenance are critical for ensuring the reliability, efficiency, and longevity of wind energy systems. As the industry continues to grow, the adoption of advanced technologies and best practices in O&M will be essential for meeting the challenges of modern wind farms. By embracing digitalization, predictive maintenance, and sustainable practices, the wind energy sector can continue to expand its role in the global transition to renewable energy, delivering clean and reliable power for generations to come.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)