As tunnel construction continues to expand in South Africa, the use of sprayed concrete, commonly known as shotcrete, has become essential for ensuring both structural integrity and safety. Shotcrete services play a critical role in reinforcing tunnel walls, improving tunnel stability, and enhancing the overall durability of underground construction projects.

What is Sprayed Concrete (Shotcrete)?

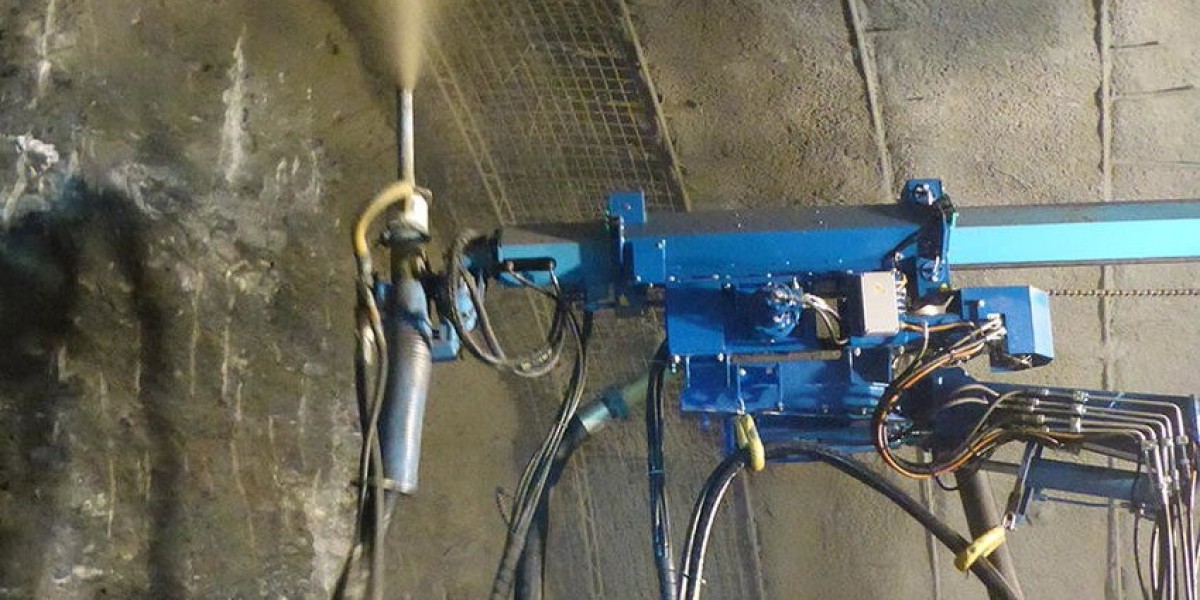

Sprayed concrete or shotcrete refers to the process of applying concrete to surfaces by spraying it through a hose at high velocity. This method allows the concrete to adhere quickly to tunnel walls, creating an immediate and strong layer of support. There are two main types of shotcrete:

- Dry-Mix Shotcrete: The dry concrete mix is sprayed through the hose, and water is added at the nozzle.

- Wet-Mix Shotcrete: The concrete is pre-mixed with water and then pumped through the hose.

Both methods are commonly used in tunneling, depending on the specific requirements of the project.

The Role of Sprayed Concrete in Tunnel Construction

Sprayed concrete is indispensable in modern tunnel construction, particularly in underground mining and civil engineering projects such as metro systems, road tunnels, and utility tunnels. Here’s why:

- Immediate Structural Support: One of the key benefits of shotcrete is that it provides immediate support during excavation. This is crucial for ensuring tunnel safety in real time, preventing collapses or rock falls that can endanger workers.

- Versatility: Sprayed concrete can be applied to irregular surfaces with ease, making it ideal for tunnel projects where traditional concrete pouring would be difficult or inefficient. Its adaptability allows for thorough coverage in even the most complex tunnel geometries.

- Durability and Strength: Shotcrete, especially when reinforced with steel fibers or mesh, forms a highly durable and strong protective layer. This is important in tunnels that will bear heavy loads or experience significant wear and tear over time.

- Waterproofing and Fire Resistance: Sprayed concrete can be enhanced with waterproofing additives and has inherent fire-resistant properties, making it a valuable material for creating safe and long-lasting tunnels.

Shotcrete Services in South Africa

In South Africa, several specialized companies offer shotcrete services tailored to tunnel construction, mining, and other underground applications. These companies provide expertise in the application of sprayed concrete to ensure optimal safety and performance in challenging underground conditions.

- Altecrete:

- Specializes in providing sprayed concrete solutions for the mining and tunneling industry. They offer a range of services including shotcrete application for underground infrastructure, particularly in mining environments.

- Services include wet and dry shotcrete application, tunnel lining, and underground support for mining shafts.

- Gunnite International:

- A well-established provider of shotcrete and gunnite services in South Africa. They cater to a range of industries including construction, mining, and civil engineering.

- Expertise in shotcrete application for tunnel walls, slope stabilization, and rock support.

- AfriSam:

- A leading supplier of construction materials, including specialized shotcrete mixes designed for high-performance use in tunneling and underground construction.

- Solutions are tailored to the specific needs of the project, ensuring that the shotcrete applied meets stringent durability and safety requirements.

- BASF South Africa:

- Known for providing advanced concrete technologies, BASF offers shotcrete solutions enhanced with admixtures to improve strength, adhesion, and durability, specifically for tunnel construction.

Importance of Shotcrete in South Africa's Tunnel and Mining Industry

South Africa’s tunnel and mining industries demand innovative and effective solutions to tackle complex geological conditions and safety challenges. The use of shotcrete is critical in these industries due to the following reasons:

- Mining Safety: Shotcrete helps secure underground shafts and tunnels in mining operations, preventing collapses and enhancing the safety of workers.

- Infrastructure Projects: Tunneling for infrastructure development such as roadways, railways, and water systems benefits from shotcrete’s ability to provide fast, reliable, and durable reinforcement.

Conclusion

Sprayed concrete or shotcrete has become a key technology in tunnel construction and mining, particularly in South Africa’s growing infrastructure and resource sectors. With a variety of expert shotcrete service providers and innovative concrete technologies available, South African projects can benefit from increased safety, durability, and efficiency in their underground operations.