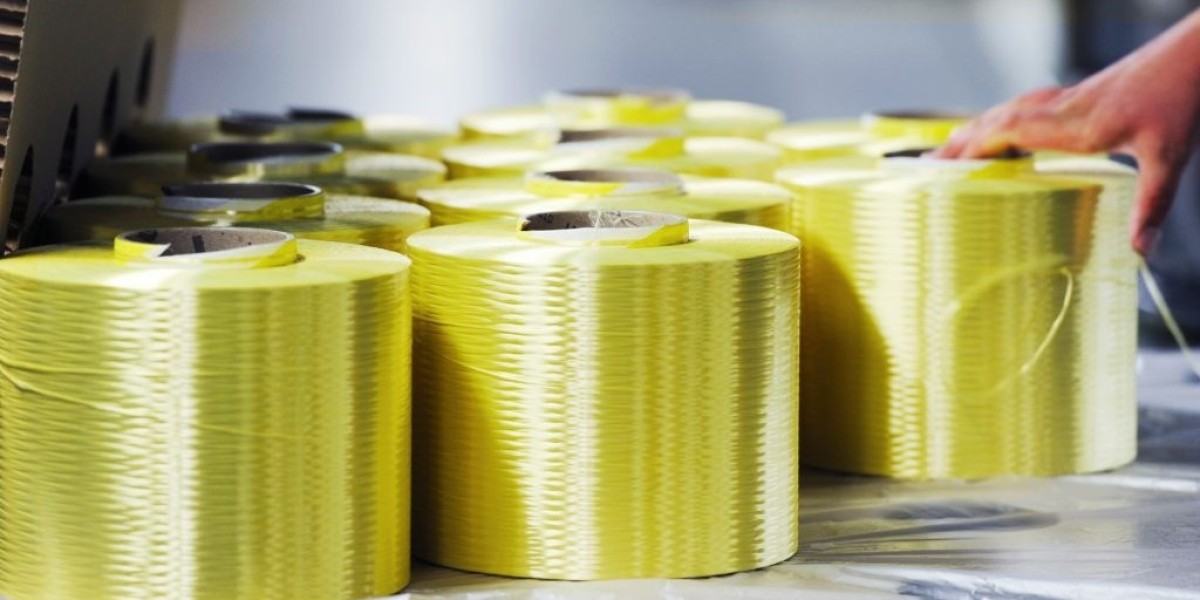

Aramid fibres, also known as aramids, are a class of heat-resistant and strong synthetic fibres. They are fibres made of polyamide polymers which have backbone chains linked by aromatic groups. Some key properties that make aramid fibres unique include their high tensile strength, low extensibility, and high resistance to heat and chemicals.

Chemical Structure and Properties

They are formed from the aniline-process of polymerization of monomers containing aromatic groups. The aromatic rings are directly linked in the polymer backbone, giving them their heat resistance and strength. The most common aramid fibres are composed of poly(p-phenylene terephthalamide) and have the repeating unit structure C10H4O-NH-C6H4-NH. The rigid aromatic groups and hydrogen bonding between Aramid Fibers linkages give fibres their high strength along the polymer chains. Their strength comes from Van der Waals forces and hydrogen bonding between polymer chains. They have a strength-to-weight ratio higher than steel and tensile strengths ranging from 2.75-3.60 GPa. They maintain their strength even at high temperatures up to around 500°F. Additionally, they have very high thermal stability and chemical resistance.

Kevlar

One of the most well-known aramid fibres is Kevlar, which was developed by DuPont in 1971. Kevlar fibres have impressive properties like high tensile strength of around 3.6 GPa, equal to the tensile strength of steel at a similar linear density.

Get more insights on- Aramid fibres

Explore More Related Article On- Dry Shampoo Market