How Industrial Dryers Work

Industrial dryers work on the principle of removing moisture from materials either by application of heat or by the circulation of air or gas. There are various types that are used depending on the type of material and required output. The most common types are rotary dryers, flash dryers, fluidized bed dryers, spray dryers, and infrared dryers.

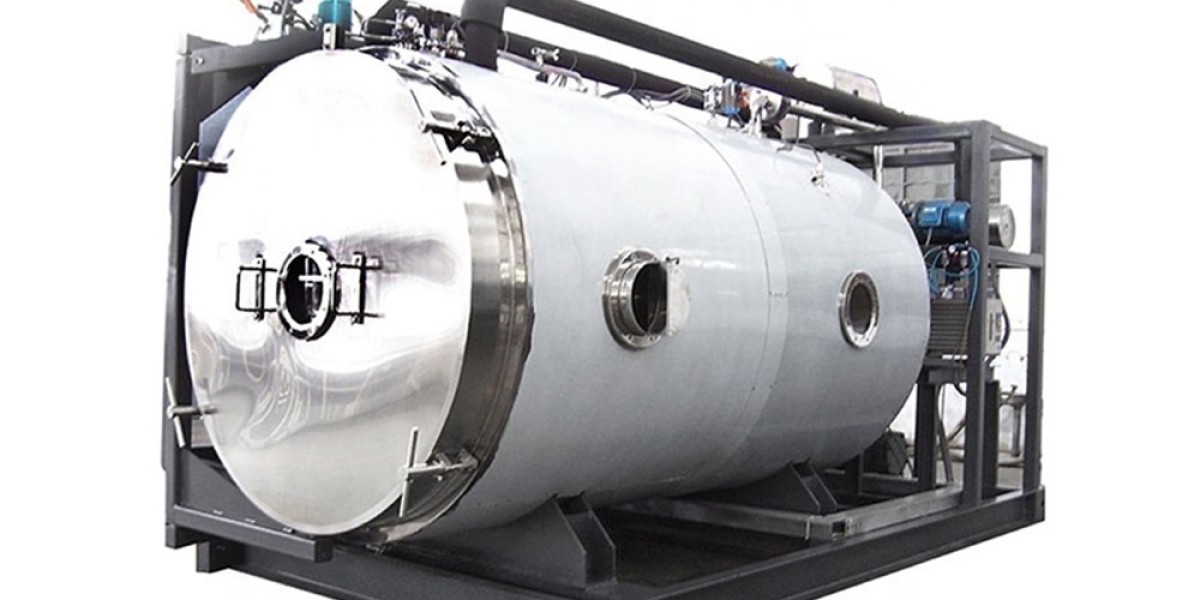

Rotary dryers consist of a slowly rotating cylindrical vessel. The wet material is fed into the cylinder and as it rotates, hot air is blown through it to evaporate the moisture. Rotary dryers are suitable for drying wet particles, granules, powders, and pastes. They provide an efficient method for continuous drying of large volumes of materials.

Flash dryers work by rapidly dispersing or "flashing" a liquid material into a heated gas stream, where the moisture is instantaneously evaporated. They are commonly used in spray drying applications to produce dry powder from slurries, solutions, or liquid dispersions. Flash Industrial Dryer offer an extremely fast drying rate for thermally stable materials.

Fluidized bed dryers work by blowing hot air from below at high velocity through a bed of wet granular material placed above, causing the materials to become fluidized and mix intimately with the heated air. As the material is kept in suspension, moisture evaporates quickly from its surfaces. They provide an efficient gentle and uniform drying for heat-sensitive materials.

Spray dryers atomize the wet feed into a spray using a nozzle and drying air and process it in a drying chamber. The high surface area of tiny droplets allows moisture to be flashed off rapidly. Spray dryers are often used to produce dry powders, granules, or agglomerates from liquid suspensions, solutions, or slurries.

Infrared dryers work by emitting infrared radiant heat to directly heat and dry materials. They effectively dry moisture from surface and are capable of providing an instant drying effect. Infrared dryers are suitable for drying sheets, coatings, films and other materials where delicate structures need to be preserved.

Role of Industrial Dryers in Key Industries

Food Processing Industry

Removal of moisture is a critical step in production of various foods including cereal, soup mixes, coffee, milk powder, spices etc. Rotary dryers and spray dryers are extensively used for drying grains, vegetables and dairy products. Fluidized bed and infrared dryers help preserve heat-sensitive nutrients and flavors during drying of fruits, herbs and other ingredients. Widespread use of industrial dryers has boosted food processing capability and production volumes.

Pharmaceutical Industry

Drying is involved in many unit operations in pharmaceutical production like granulation, coating, and microbial inactivation. Spray dryers produce dry powders from active pharmaceutical ingredients and excipients. Fluidized bed dryers are used for drying granules before tableting. Proper drying is important to maintain consistency and stability of active components in final drug products. Reliable industrial dryers ensure stringent quality standards are met.

Chemical Industry

Moisture removal plays a key role in manufacturing of dyes, pigments, expolosives, and other chemical products. Rotary dryers are commonly used for drying precipitates from reactions. Infrared dryers find application in drying paints and coatings. They enable continuous operation and precise moisture control, increasing production efficiency of chemical plants.

Pulp and Paper Industry

At various stages like pulping, sheet forming, coating and calendaring; moisture needs to be reduced to required levels. Roller dryers and through-air dryers are integral part of paper machines for dewatering pulp and drying paper sheets. Thermal treatment in dryers enhances printability and end-use properties of finished paper products.

Other Industries

They also see widespread adoption in cement and ceramic manufacturing. In textiles, they are used for drying fibers, yarns and final fabrics. Mining operations employ dryers to concentrate ores. Waste treatment facilities rely on drying for volume reduction before further processing or disposal. Across diverse industries, dryers play a critical role in manufacturing workflows by facilitating downstream processing and preserving quality of dried materials.

Operational Considerations

Proper selection and operation of industrial dryers is important to achieve desired drying performance and maximize productivity. Factors like material type, moisture content, heating medium compatibility, temperature limits, batch vs continuous operation need evaluation. Uniform air distribution, drying controls and exhaust management require attention. Regular maintenance keeps dryers running optimally. Automation enables close monitoring and recording of process parameters. Overall, adhering to best practices helps ensure industrial dryers deliver consistent, quality dried output essential for various manufacturing activities.

Get More Insights on Industrial Dryers

Choose Preferred Language for better understanding-

About Author-

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)