In the world of manufacturing, product customization, and branding, precision is everything. Businesses are continually looking for methods that can provide high-quality, detailed, and durable results while being efficient and cost-effective. One such advancement that has revolutionized this process is the fiber laser engraver. This technology offers exceptional precision, speed, and versatility, making it the ideal choice for industries that require high-quality markings on various materials. In this post, we’ll explore what a fiber laser engraver is, how it works, and why it’s an essential tool for businesses across industries. Let’s dive into the powerful world of fiber laser engraving.

What is a Fiber Laser Engraver?

A fiber laser engraver utilizes a fiber-optic cable as the primary medium for generating the laser beam. The fiber-optic cable amplifies light from a laser diode, allowing the system to create an extremely focused and powerful laser beam that can be used for engraving, marking, cutting, and etching various materials. Unlike traditional CO2 lasers, fiber lasers use a solid-state medium that offers several distinct advantages, including better energy efficiency, a longer lifespan, and the ability to mark a wider range of materials with greater precision.

Key Advantages of Using a Fiber Laser Engraver

Precision and Accuracy The primary reason businesses turn to fiber laser engravers is their unparalleled precision. The tightly focused laser beam allows for highly detailed and intricate markings on various materials, from metals and plastics to ceramics and glass. This high level of accuracy makes fiber laser engravers perfect for applications requiring fine engraving, such as serial numbers, logos, and barcodes on small items like jewelry, electronics, and industrial parts.

Versatility in Material Compatibility Fiber laser engravers are extremely versatile in terms of material compatibility. They can mark and engrave a wide range of materials, including metals (such as stainless steel, aluminum, brass, and titanium), plastics, ceramics, and even some types of glass. This versatility makes fiber lasers a go-to solution for industries ranging from automotive and aerospace to electronics, healthcare, and consumer goods.

Speed and Efficiency In a fast-paced manufacturing environment, time is money. Fiber laser engravers are known for their speed and efficiency. Compared to traditional engraving methods, fiber lasers can perform tasks faster, with minimal wear and tear. The reduced processing time allows businesses to increase production throughput, offering more consistent quality with reduced costs. Additionally, fiber lasers offer a high level of automation, meaning that tasks can be completed without continuous manual intervention, further boosting efficiency.

Minimal Maintenance One of the standout features of fiber laser engravers is their low maintenance requirements. Fiber lasers have no moving parts, and the fiber-optic technology used in these systems ensures high reliability and minimal risk of failure. With a longer lifespan compared to other laser types, fiber lasers require less frequent servicing and replacement of components, making them a cost-effective long-term investment for businesses.

Energy Efficiency Energy efficiency is crucial for businesses looking to reduce their operating costs. Fiber laser engravers are known for their energy efficiency. They consume less power than CO2 lasers, reducing electricity bills without sacrificing performance. The high efficiency of fiber lasers makes them an environmentally friendly option, helping businesses lower their carbon footprint while maintaining high productivity.

High-Quality Markings The quality of the marks produced by fiber laser engravers is exceptional. Unlike other types of laser engravers, fiber lasers create permanent, clean, and crisp marks that are resistant to wear, fading, and corrosion. This durability makes them ideal for applications where the markings need to withstand harsh conditions, such as parts used in outdoor or industrial settings.

Applications of Fiber Laser Engraving

Industrial and Manufacturing Markings One of the most common applications for fiber laser engravers is in the industrial and manufacturing sectors. Fiber lasers are used to mark serial numbers, barcodes, QR codes, and logos on various parts and products. These marks are permanent, making them ideal for product traceability and brand identification. Whether it’s marking metal parts in the automotive industry or components in the aerospace sector, fiber laser engravers offer the precision needed for high-stakes applications.

Electronics and Circuit Boards In the electronics industry, fiber laser engravers play a crucial role in the precise engraving of components like circuit boards, chips, and microelectronics. The fine engraving capabilities of fiber lasers ensure that even the smallest components can be marked with logos, part numbers, and other identifying information, which is crucial for inventory management and quality control.

Medical Devices and Instruments The medical industry also benefits greatly from fiber laser engraving. The precision of fiber lasers ensures that medical instruments and devices, such as syringes, surgical tools, and implants, can be accurately marked with essential information, including serial numbers, expiration dates, and manufacturer details. These marks are crucial for patient safety, regulatory compliance, and traceability.

Jewelry and Personalized Items For businesses that specialize in custom jewelry or personalized gifts, fiber laser engravers offer the ability to create intricate designs and engravings on small, delicate items. Whether it’s engraving a name on a bracelet or etching a custom design on a piece of jewelry, fiber lasers offer the precision and finesse needed to produce high-quality, personalized products.

Plastic and Packaging Industries In the plastic and packaging industries, fiber laser engravers are used for marking plastic components, containers, and packaging with logos, product information, and barcodes. Unlike traditional printing methods, laser engraving ensures that the markings are permanent, even in challenging environments such as shipping or handling.

Why Choose the Lumitool Optical Fiber Laser Marking Machine?

For businesses looking to invest in a high-performance fiber laser engraver, the Lumitool Optical Fiber Laser Marking Machine stands out as an excellent choice. Here’s why:

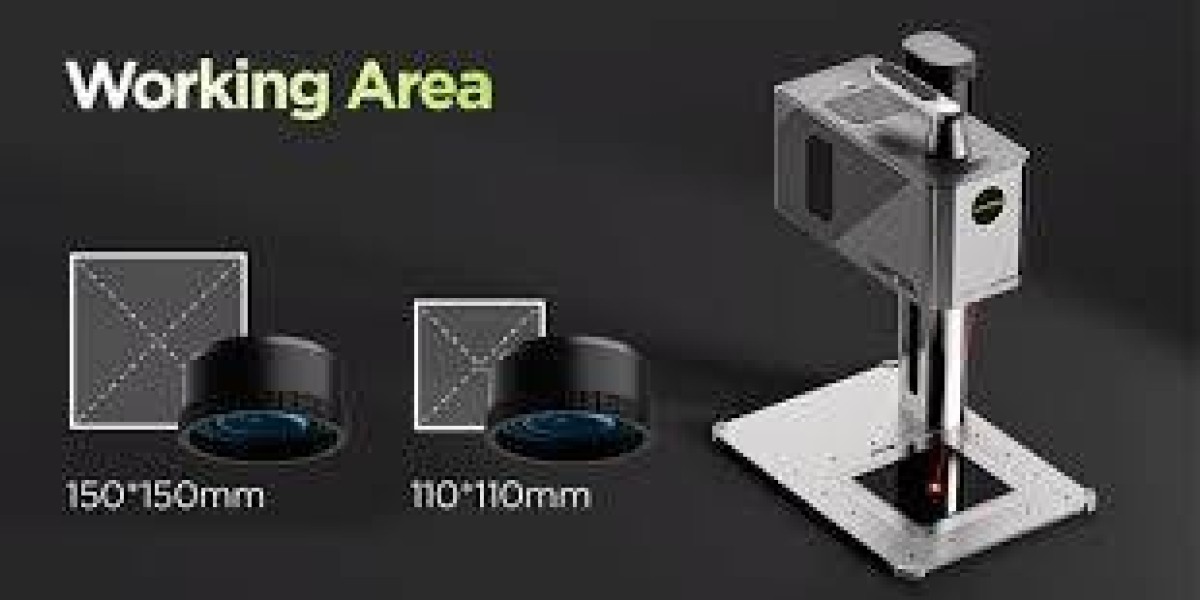

High Precision and Reliability The Lumitool Optical Fiber Laser Marking Machine delivers extremely accurate and detailed markings on a wide range of materials, from metals to plastics. With high-speed capabilities and minimal heat output, it ensures that every engraving is clear, sharp, and precise, meeting the highest industry standards.

Durability and Long Lifespan Lumitool’s fiber laser machines are designed for durability and long-term use. With a robust construction and advanced cooling technology, these machines are built to last, even under the demands of high-volume production environments.

User-Friendly Interface The Lumitool Optical Fiber Laser Marking Machine comes with an intuitive interface that makes it easy for operators to set up and manage engraving jobs. With minimal training required, businesses can quickly integrate this machine into their production lines, improving productivity without the need for extensive learning curves.

Customizable Settings The machine offers customizable engraving settings, allowing businesses to adjust the speed, depth, and intensity of the laser beam to achieve the desired results. This flexibility ensures that the Lumitool Fiber Laser Marking Machine can meet the specific needs of various industries.

Energy Efficiency The Lumitool Optical Fiber Laser Marking Machine is designed with energy efficiency in mind, ensuring businesses can lower operational costs while maintaining high productivity. The low power consumption and high output ensure that businesses get the most out of their investment.

Conclusion

The fiber laser engraver is a game-changer for businesses looking to improve their marking and engraving processes. From high-precision applications to energy efficiency and minimal maintenance, fiber lasers offer unparalleled advantages across industries. Whether you’re in manufacturing, electronics, medical devices, or jewelry, the Lumitool Optical Fiber Laser Marking Machine provides the tools you need to achieve exceptional results with speed, accuracy, and efficiency. If you’re looking to elevate your business operations and achieve top-quality engravings, investing in a fiber laser engraver is a smart choice.