In the world of semiconductor machining, every detail counts. As industries grow more dependent on small and powerful technologies, precision and quality control have become key to producing reliable and effective components. In semiconductor machining, where microscopic tolerances are critical, ensuring each piece meets exact standards makes a huge difference in the final product.

The Role of Precision in Manufacturing Semiconductor Parts

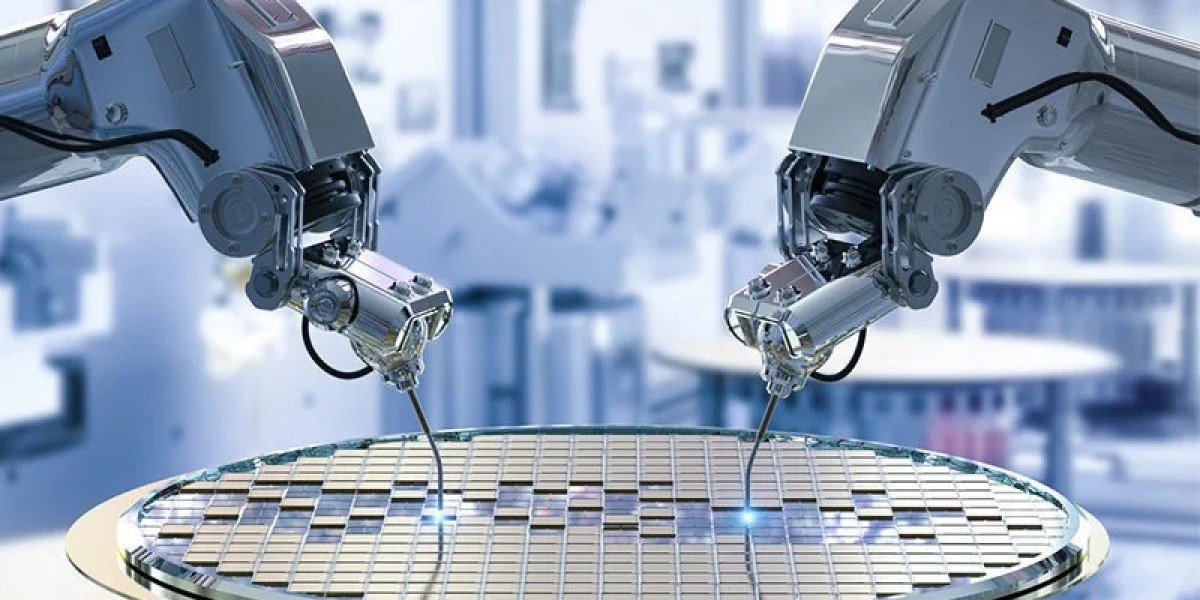

When manufacturing parts for semiconductors, workers rely on high-tech equipment to shape, cut, and refine the materials. One of the main challenges in this field is working with materials that are incredibly hard to handle, like silicon and other alloys. Precision ensures these materials are processed to the exact dimensions and shapes needed for optimal performance.

Using machines that can achieve incredibly small tolerances means there’s little room for error. For example, a fraction of a millimeter too much or too little could lead to malfunctions or inefficiencies. In the fast-moving tech industry, even small defects can lead to big problems down the road, which makes precision a priority at every step.

Quality Control in Semiconductor Machining

Quality control is essential in semiconductor machining because it helps identify problems before they affect the end product. During each phase of the machining process, the parts are tested to check for possible defects. Inspections and tests are often done using specialized tools, like laser scanners, to ensure everything is perfect.

By carefully examining each part, manufacturers prevent errors from sneaking into the production process. This gives both businesses and consumers peace of mind, knowing that they’re getting a product that has been checked for quality and reliability.

With more tech devices relying on powerful and durable chips, quality control has a direct effect on performance. Consistency ensures the machines behave as expected, which prevents costly issues in the long run.

Linking Semiconductor Machining and Other Industries

Precision in machining doesn’t just affect the semiconductor industry — it plays a role in many other fields as well. One good example is the production of magnetic beads, which are used in various applications, including health and industrial processes. Just like semiconductor parts, these beads need to be manufactured with precision and care to ensure they perform their intended function.

Magnetic bead manufacturers face similar challenges when it comes to accuracy in their production process. Small flaws in the beads can result in failure or inefficiencies, especially when they are used in critical applications like diagnostics or medical equipment. The importance of quality control in the machining process remains just as essential for these manufacturers.

Summing Up: Precision and Quality Control Across Industries

The world of semiconductor machining offers valuable lessons in the importance of precision and quality control. With a small mistake capable of impacting the function of complex systems, ensuring accuracy and consistency has become the norm for successful manufacturers. Whether it’s tiny chips in smartphones or magnetic beads for industrial use, these principles extend far beyond semiconductors.

In industries like semiconductor machining and magnetic bead manufacturing, quality control and precision play a vital role in guaranteeing performance and reliability. Both industries rely on high standards to deliver products that meet the needs of a tech-driven world. So, when the importance of quality hits home, we begin to understand how every part — no matter how small — is critical to the big picture.