Sheets of High-Density Polyethylene (HDPE) are well known for their strength, adaptability, and low weight. These features make them an essential material in various industries, from construction to packaging and even everyday household applications. HDPE sheets combine strength and flexibility, ensuring optimal performance in demanding conditions.

In this article, we explore the unique properties of HDPE sheets, their diverse applications, and the benefits of choosing this material. We will also integrate keywords such as Plastic HDPE Sheets, HDPE plastic sheets, and HDPE Sheets plastic to emphasize their value in industrial and commercial settings.

Understanding HDPE Sheets

HDPE sheets are thermoplastic polymers derived from petroleum. Known for their high strength-to-density ratio, these sheets are lightweight yet incredibly strong, resistant to impact, and adaptable to various uses. Their ability to withstand environmental stress without compromising quality makes HDPE sheets a preferred choice for both indoor and outdoor applications.

Key Features of HDPE Sheets

- Lightweight

Despite their strength, HDPE sheets are remarkably lightweight, which facilitates easy handling and installation. - Durability

HDPE plastic sheets are resistant to wear and tear, UV radiation, and chemical exposure, making them ideal for long-term use. - Waterproof

Their non-porous surface prevents water absorption, ensuring excellent performance in moisture-prone environments. - Eco-Friendly

Because HDPE sheets are recyclable, they support environmentally friendly production and waste disposal methods. - Versatility

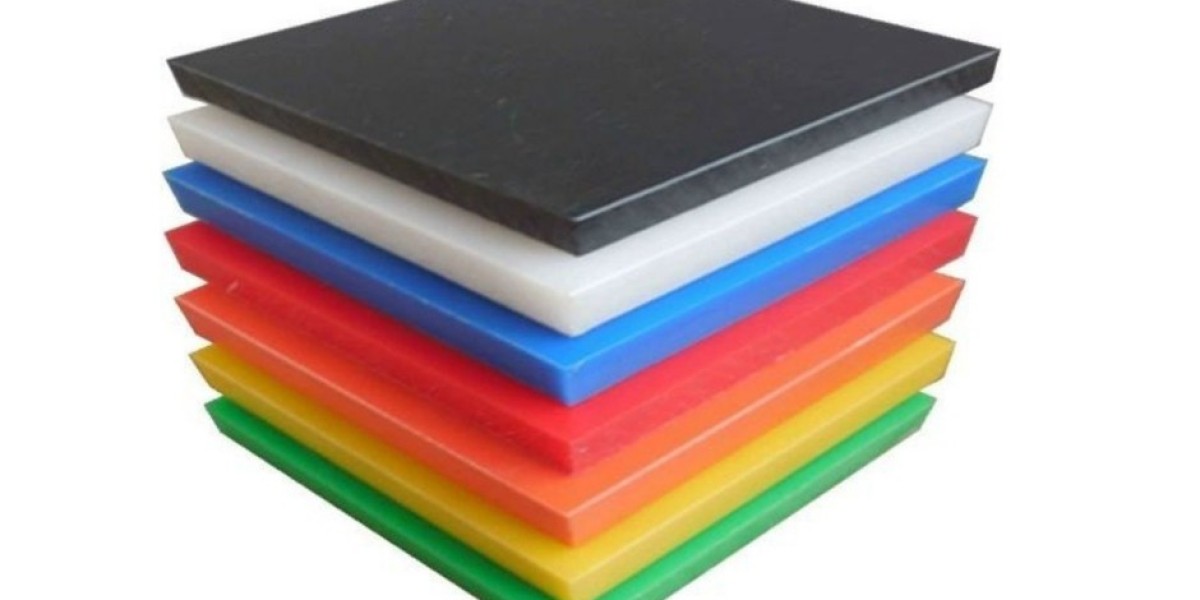

Available in various thicknesses and sizes, HDPE sheets can be customized for specific needs.

Common Applications of HDPE Sheets

1. Construction and Building

HDPE sheets are extensively used in construction due to their strength and resistance to harsh environmental conditions. From waterproofing foundations to lining reservoirs, HDPE Sheets plastic play a critical role in ensuring structural integrity.

2. Packaging Industry

Lightweight and food-safe, plastic HDPE Sheets are a go-to material for packaging solutions. They provide a protective barrier against moisture and contaminants, keeping products fresh and intact.

3. Agricultural Applications

Farmers rely on HDPE plastic sheets for creating irrigation canals, pond liners, and greenhouse covers. Their durability and resistance to chemicals make them suitable for agricultural environments.

4. Marine and Aquatic Uses

HDPE sheets are often employed in marine applications, including docks, boat linings, and fish tanks. Their waterproof and UV-resistant properties ensure longevity in water-based environments.

5. Industrial Manufacturing

Industries use HDPE sheets for fabricating machine parts, storage tanks, and conveyor belts due to their excellent machinability and resistance to abrasion.

6. Household Applications

From cutting boards to storage containers, HDPE plastic sheets find everyday use in homes, thanks to their non-toxic and easy-to-clean surface.

Benefits of Using HDPE Sheets

1. Cost-Effectiveness

HDPE sheets offer an affordable solution for applications that demand durability and performance. Their low maintenance requirements further reduce costs over time.

2. Resistance to Corrosion

Unlike metal, HDPE sheets do not rust or corrode, making them suitable for environments exposed to water or chemicals.

3. Customizability

With the ability to mold, cut, and weld, HDPE sheets can be tailored to meet specific industrial or personal needs.

4. Environmental Sustainability

Recyclable and reusable, HDPE sheets contribute to reducing plastic waste and supporting eco-friendly practices.

5. Long Lifespan

HDPE sheets are built to last, even in challenging conditions, offering a long-term solution for various applications.

How to Choose the Right HDPE Sheets

When selecting HDPE sheets for a project, consider the following factors:

- Thickness and Size

Depending on the planned use, choose the right thickness and size. While thinner sheets are appropriate for lightweight applications, thicker sheets are best for heavy-duty applications. - Grade

HDPE sheets come in different grades, such as food-grade, marine-grade, and industrial-grade. Select the one that best suits your unique needs. - Supplier Reputation

Source HDPE sheets from a trusted manufacturer to ensure quality and consistency. Reliable suppliers provide sheets that meet industry standards and offer customization options. - Environmental Conditions

Consider factors such as temperature, UV exposure, and chemical interactions to select sheets with suitable resistance properties.

HDPE Sheets vs. Other Materials

When compared to materials like PVC, acrylic, or metals, HDPE sheets stand out due to their unique combination of features:

- Weight: HDPE sheets are lighter than metals, making them easier to handle and transport.

- Durability: They outperform acrylic and PVC in terms of resistance to impact and chemicals.

- Flexibility: Unlike rigid materials, HDPE sheets can be easily molded or shaped.

- Cost: They are more affordable than many alternatives without compromising on quality.

Conclusion

HDPE sheets are a reliable and versatile material that caters to diverse needs across industries and households. Their lightweight nature, durability, and adaptability make them a preferred choice for construction, packaging, agriculture, and more.

By opting for high-quality plastic HDPE Sheetss from a trusted supplier, you can enjoy the benefits of a cost-effective, long-lasting solution tailored to your requirements. Whether you need waterproofing for a project or durable material for manufacturing, HDPE sheets provide the strength and performance necessary to meet your goals.

As we continue to seek sustainable and efficient materials, HDPE sheets stand out as an eco-friendly option that delivers on all fronts. Make the smart choice today and experience the unmatched benefits of this exceptional material.

Frequently Asked Questions

Q1: What makes HDPE sheets ideal for outdoor applications?

A: HDPE sheets are UV-resistant, waterproof, and durable, ensuring they can withstand harsh weather conditions. These properties make them perfect for outdoor uses such as roofing, pond liners, and marine equipment.

Q2: Are HDPE sheets safe for food-related applications?

A: Yes, HDPE sheets are non-toxic and food-safe, making them suitable for cutting boards, food packaging, and storage containers. Ensure you use food-grade HDPE sheets for such purposes.

Q3: How can I ensure the longevity of HDPE sheets?

A: To maximize the lifespan of HDPE sheets, clean them regularly, avoid exposure to extreme heat, and source high-quality sheets from a reputable supplier. Proper installation and maintenance are also crucial.