Albuterol, a vital pharmaceutical compound, is widely used in the treatment of respiratory conditions such as asthma and chronic obstructive pulmonary disease (COPD). With the growing global demand for effective respiratory medications, understanding the Albuterol production cost is critical for businesses aiming to optimize their manufacturing processes and enhance profitability. This article delves into the cost model, pre-feasibility, industrial trends, labor charges, utilities, logistics, and supply chain considerations integral to Albuterol production.

A well-defined cost model provides a structured framework for estimating and analyzing the various expenses involved in producing Albuterol. The cost structure typically encompasses the following components:

Raw Materials: The primary ingredients for synthesizing Albuterol include intermediates and chemical reagents. Raw material costs often constitute a significant portion of the overall production expense.

Labor Charges: Skilled labor is required for managing complex chemical synthesis processes. Labor costs vary based on regional wage standards and the availability of qualified personnel.

Utilities: Manufacturing Albuterol involves energy-intensive processes such as heating, cooling, and distillation. Utilities like electricity, water, and gas are critical cost contributors.

Logistics and Supply Chain: Efficient transportation and supply chain management ensure the timely delivery of raw materials and finished products, impacting overall production costs.

Fixed Costs: These include expenses related to plant setup, equipment maintenance, and depreciation.

Regulatory Compliance: Adhering to stringent pharmaceutical industry standards requires additional investment in quality control and compliance measures.

Request a Free Sample - https://www.procurementresource.com/production-cost-report-store/albuterol/request-sample

Conducting a pre-feasibility study is a crucial step before initiating Albuterol production. This process involves evaluating technical, financial, and operational aspects to determine project viability. Key factors considered in pre-feasibility studies include:

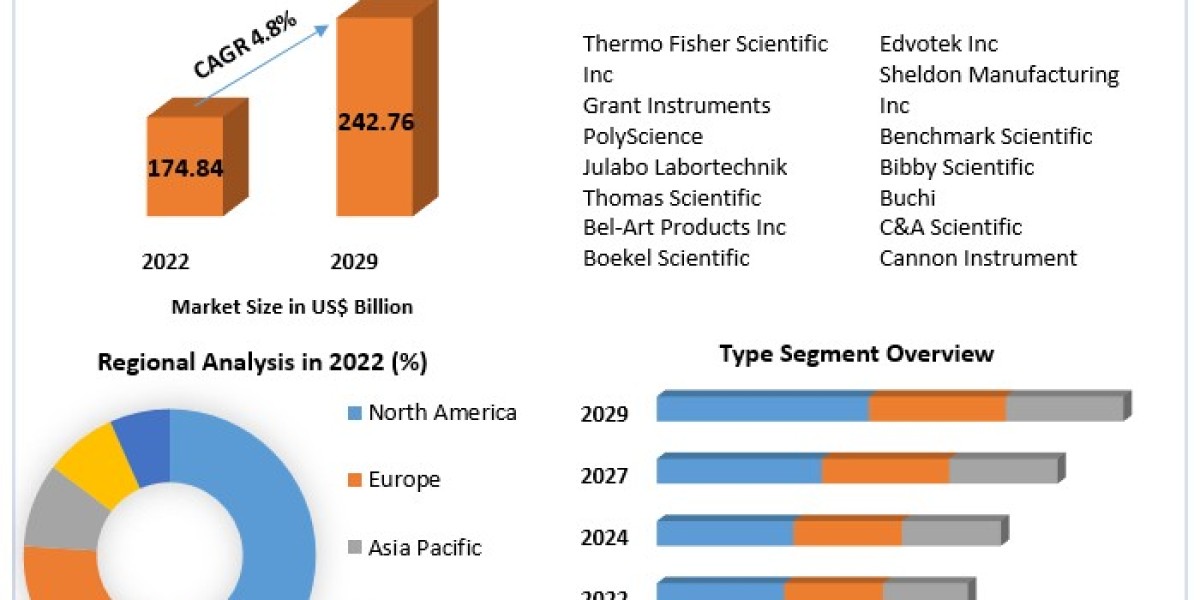

Market Demand Analysis: Understanding the global and regional demand for Albuterol helps manufacturers plan production volumes effectively.

Technology Assessment: Selecting the right technology and production methods can significantly reduce costs and improve efficiency.

Investment Requirements: Estimating capital and operational expenditure ensures financial preparedness.

Risk Analysis: Identifying potential risks, such as supply chain disruptions or regulatory challenges, helps in devising mitigation strategies.

The pharmaceutical industry is witnessing several trends that influence Albuterol production:

Adoption of Advanced Manufacturing Techniques: Innovations such as continuous manufacturing and process automation are enhancing production efficiency and cost-effectiveness.

Focus on Sustainable Practices: Companies are prioritizing eco-friendly production methods to reduce environmental impact and align with global sustainability goals.

Increasing Demand in Emerging Markets: Rising prevalence of respiratory disorders in developing regions is driving the need for cost-effective Albuterol production.

Labor charges significantly affect the overall production cost of Albuterol. Factors influencing labor costs include:

Regional Wage Disparities: Production facilities in regions with lower labor costs may achieve cost advantages.

Skill Level Requirements: The complexity of Albuterol synthesis necessitates hiring skilled professionals, which can increase labor expenses.

Workforce Efficiency: Investing in employee training programs can enhance productivity and optimize labor costs over time.

Utilities form a substantial part of the operating expenses in Albuterol manufacturing. Key utility considerations include:

Energy Consumption: Processes like chemical reactions, distillation, and drying are energy-intensive, making energy costs a critical factor.

Water Usage: Purified water is essential for various stages of production, including cleaning, formulation, and quality control.

Waste Management: Proper disposal of chemical waste is necessary to meet environmental regulations, adding to utility expenses.

Logistics and Supply Chain Management

Efficient logistics and supply chain management are vital for minimizing Albuterol production costs. Strategies to optimize these elements include:

Strategic Sourcing: Procuring raw materials from reliable suppliers ensures consistency in quality and cost.

Transportation Optimization: Streamlining transportation routes and modes can reduce delivery time and expenses.

Inventory Management: Maintaining optimal inventory levels prevents overstocking and minimizes holding costs.

The role of procurement resource platforms cannot be overstated in this context. These platforms provide valuable insights and tools for sourcing materials, managing suppliers, and optimizing the supply chain

To gain deeper insights into the cost structure of Albuterol production and explore tailored solutions for your business, request a free sample report. This comprehensive sample includes detailed cost analysis, market trends, and strategic recommendations to enhance your production efficiency.

Request Your Free Sample Report - https://www.procurementresource.com/production-cost-report-store/albuterol/request-sample

Contact Us:

Company Name: Procurement Resource

Contact Person: Tom Hanks

Email: [email protected]

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA