Metal stamping production is a production process that uses punches and molds to deform or break iron, aluminum, copper, and other plates and heterosexual materials to achieve a certain shape and size. Stamping is called sheet forming in foreign countries. The so-called plate forming refers to a forming method in which a plate, a wall tube, a thin profile, etc. are used as raw materials for plastic processing. The cold stamping technology of metal stamping production is also important.

Metal stamping production is cold stamping first. From small stainless steel fast food trays to large car covers, the car shells you see are all stamped out with dies. This mold is divided into two parts, the upper mold, and the lower mold. Install the upper and lower molds on the press, use the press to separate the molds, and put on the sheet metal, that is, iron, steel or stainless steel, and other hardware materials. Once the press is pressed, metal stamping production will come out.

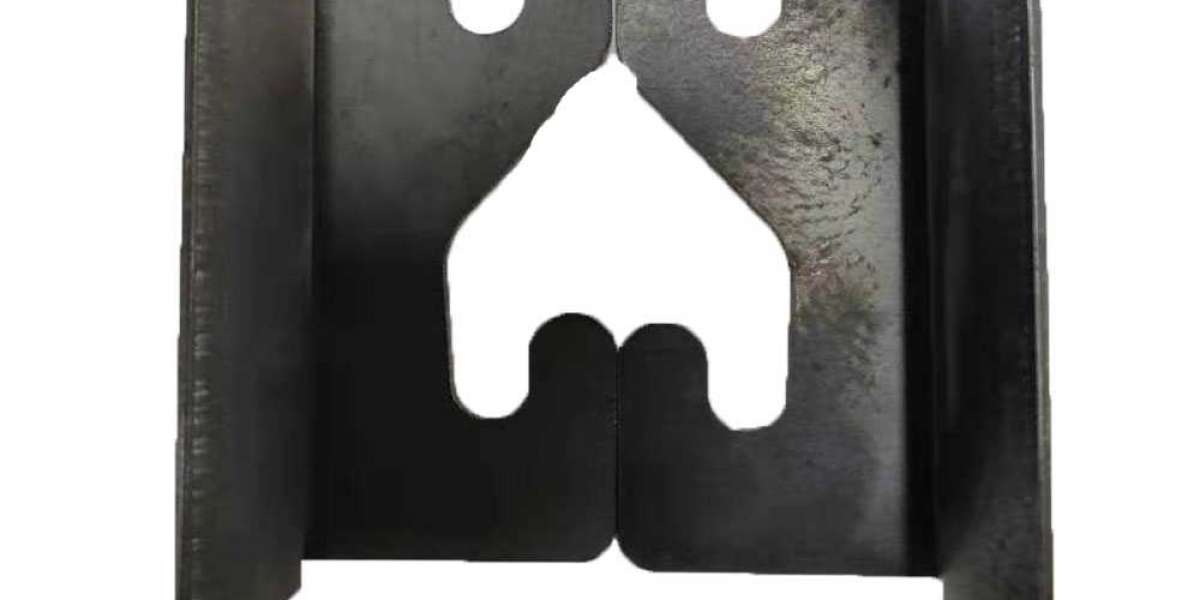

Metal stamping parts are light in weight, thin in thickness, and good in stiffness. The dimensional tolerance of metal stamping production is guaranteed by the mold, so the quality is stable, and it can generally be used without mechanical cutting. The metal structure and mechanical properties of cold metal stamping parts are better than the original blanks, and the surface is smooth and beautiful. The tolerance level and surface condition of cold metal stampings are better than those of hot metal stampings.

The metal stamping production of large quantities of medium and small parts generally adopts composite molds or multi-station continuous molds. Centered on a modern high-speed multi-station press, it is equipped with strip uncoiling, straightening, finished product collection, conveying, mold library, and rapid mold changing device, and is controlled by computer programs to form a fully automatic metal stamping production line with high productivity. Using new mold materials and various surface treatment technologies, and improving the mold structure, a metal stamping die with high precision and long life can be obtained, thereby improving the quality of metal stamping production and reducing the manufacturing cost of metal stamping parts.

The process and equipment of metal stamping production are constantly developing. In addition to the traditional use of presses and steel molds to manufacture metal stamping parts, hydroforming, and spinning, superplastic forming, explosion forming, electro-hydraulic forming, electromagnetic forming, etc. The special metal stamping forming process has also developed rapidly, raising the technical level of metal stamping production to a new level. The special metal stamping forming process is especially suitable for the production of various kinds of small and medium batch parts. For the ordinary metal stamping processes, simple molds, low melting point alloy molds, group molds, and metal stamping flexible manufacturing systems can be used to organize metal stamping production of various types of small and medium-sized parts.

In short, metal stamping production has a series of advantages such as high efficiency, low processing cost, high material utilization rate, simple operation, and easy realization of mechanization and automation. If you have any questions about metal stamping production, please feel free to contact us, Zhongshan YingYunHardware will provide you with quality service.