Well, we have a really cool jig that we are setting up, and I thought you might be interested in seeing what we have because knowledge is power, and a lot of mechanics out there just need to see something in order to implement it and not only save money, but also make money for your company your company all right, so now the one thing I would say is that when you look at the machinists and the programmers you will see that they are all very creative. So now the one thing I wouldIn fact, it's a monster hook that doubles up as a twin hook. The hook has a unique shape, which I think is really cool.

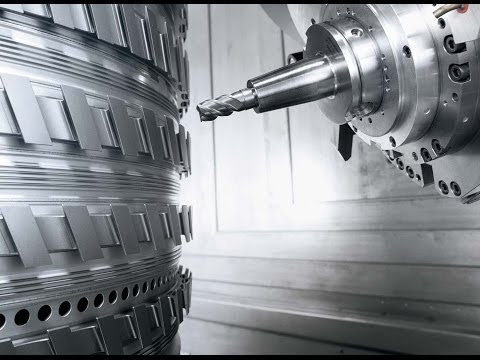

When many people see it, they are perplexed because they think toCNC machiningthemselves, "Wait a minute, you're carrying this guy," and "I understand that this piece of material is going to turn into this piece of material, but how are you going to hold this part in place so that you can cut off the back part?" They are right. First and foremost, CNC machining we have a base plate, which is where the art of jigging takes place right here.

It takes time to lock everything down, which you may have heard is a good thing, but it is true. The 500lb titanium octopus beast being roughed up on a machine right there is what I'm doing for this video, which is pretty cool, don't you think?

From the perspective of the past, I placed the CNC machining services VeroS system on the table, okay, all kinds of different systems, all from Shunks, and while BOOM is playing, I'm showing you guys how simple it is to use the vise with these pins on it. These pins are actually used to insert it into the system, and then the air driveCNC machining servicesis functional as a result of my installation.

What do you think? I believe you are correct. Let's take our old fixtures and turn them into barrel fixtures. Okay, so we took this guy down, flipped him over, and machined these two pockets right here. The threads on this thing have to be absolutely perfect, and this thing has to fit nice and snug right inside this guy.

delwyyknran

26 Blog posts