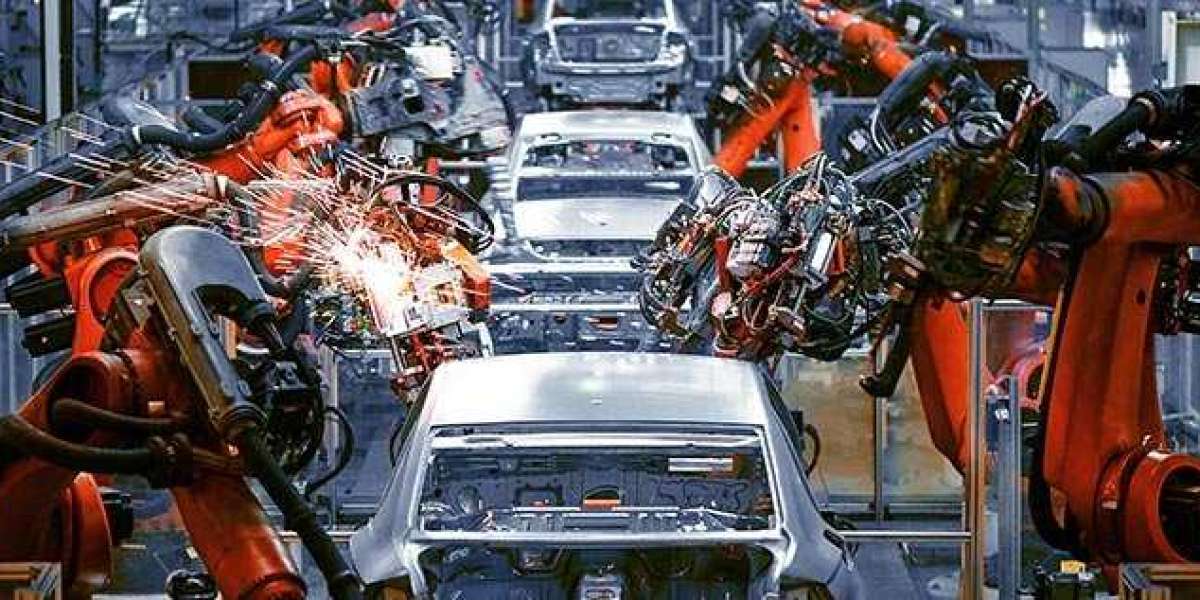

In manufacturing, low-volume production is used for many purposes, including the development of new technologies and products. Examples of low-volume production include the production of DRAM chips for mobile phones and other devices. Another example is the production of automobiles.

Cost-effectiveness

Low-volume manufacturing is an excellent way to test new products and refine them before mass production. It allows companies to develop a cost-effective production process and budget. It can also be an effective way to refine and simplify best practices. It can also reduce overhead production costs. In addition, it can help improve the quality of a product.

Low-volume manufacturing also enables companies to access new markets before the competition, reducing overall production costs and reducing the lead time. These benefits make it a good choice for many companies in different industries. A key benefit of low-volume manufacturing is that it allows companies to iterate designs more quickly. This helps them to keep their businesses financially stable.

Another advantage of low-volume manufacturing is that it requires fewer production tools. This means that they are more affordable for small companies. Low-volume manufacturing is also flexible, allowing companies to change their product design without worrying about inventory. Moreover, low-volume manufacturers do not have a minimum order requirement.

Human error countermeasures

Human error can be extremely challenging to prevent, detect, and manage. People perform at different levels of consistency and capacity, making it nearly impossible to eliminate the risk completely. However, there are several steps that companies can take to prevent or minimize human errors. First, they must identify the causes of human errors. Errors can come in a variety of forms, such as slips, omissions, and commissions.

Human error is a serious threat to any system. In fact, it's responsible for 52% of all data and security breaches. Not only that, but it's the cause of a plethora of notorious tragedies. Since human error can strike at any time, companies cannot afford to take random chances. By implementing human error countermeasures, companies can ensure their operations run smoothly and maximize profitability.

Human error occurs when human failures cause a deviation from procedures and standards. When these deviations cause an accident or damage to a product, the consequences can be severe. Almost every major accident has its root in human failure, and companies must manage this risk with the same rigor as technical measures.

Reduced risk

Low volume production is a cost-effective manufacturing process that can help bridge the gap between design and production. It helps companies reduce the risks associated with manufacturing, as well as improve design flexibility and speed time to market. The process is especially useful in industries with long supply chains. Apple, for example, used low-volume production to reduce the number of colors and sizes available for its new Apple Glass product, while also reducing manufacturing costs. However, it's important to note that low-volume manufacturing is not appropriate for every product.

In addition to reducing initial investment costs, low volume production allows companies to develop new products more cost-effectively by testing them in smaller quantities. By producing smaller quantities, a company can determine if a new product is popular and profitable before investing in full-scale production. This can also reduce the risk of holding unsold inventory.

Low-volume production also speeds up the development and launch of new products. This is especially important in a competitive marketplace where being first to market is essential. Since lead times are short, low-volume production allows products to hit shelves quicker than full-scale production. In addition, it reduces the risk associated with high-volume production, which can be expensive and has a long lead time.

Faster product launch

With the speed of technological change increasing, companies need to keep up with the competition. As a result, timing becomes a crucial factor in launching a new product. An early product launch will allow it to gain market share and make potential buyers more familiar with its features and benefits. Besides, faster sales will mean higher profits. With this in mind, product developers are under increasing pressure to come up with new designs and modify existing ones.

Low-volume production can also provide the needed push for new product launches. It allows for quick release of the first batch to test customer response, while preparing for mass production. A new product can be launched much faster if it has been tested in a small batch. Moreover, the smaller batch size enables it to meet customer expectations faster, which helps in establishing long-term relationships and increasing revenues.