Overview:

Dietary fiber laserlight marking machines industrial facilities are locations focusing on producing higher than average-prime quality roughage laser beam marking models applied to unique businesses. These machines use more advanced lazer modern advances to level a range of materials, integrating metal, plastic-type material, and fiber laser printer in some cases glass. They really are basic instruments in today's making arena, when they present you with a straightforward, exact, and valuable strategy to indicatesegments and products, and ingredients. This article discuss how roughage laserlight marking appliance factories perform the job, their usefulness, in addition to their influence over the developing arena.

How Fiber content Laserlight Marking Units Perform the job:

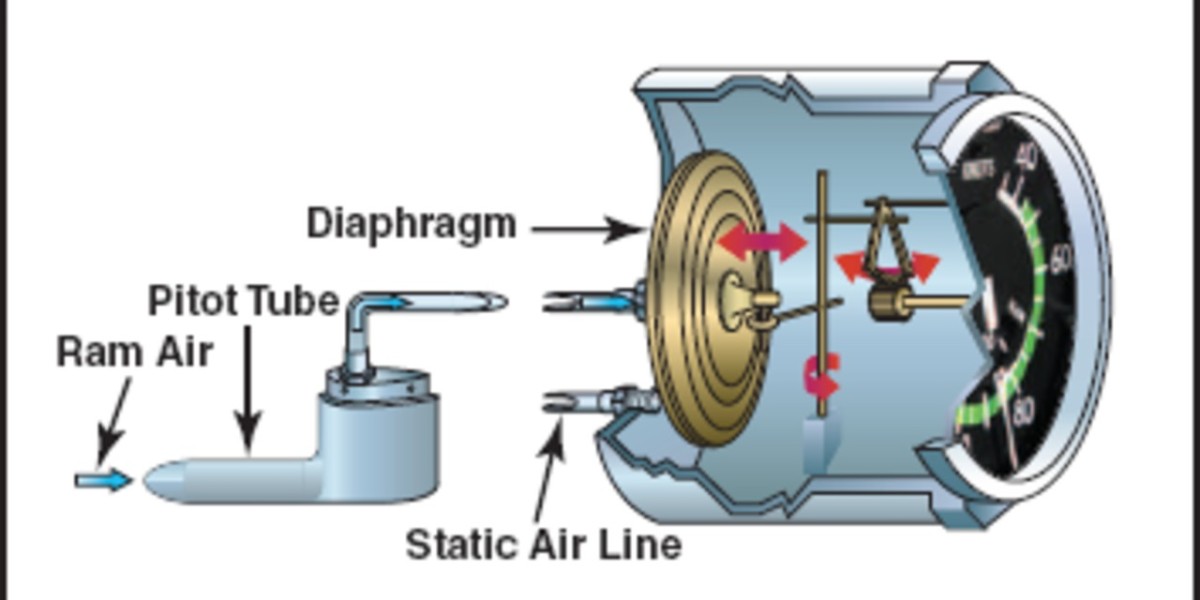

Roughage laser beam marking equipments make use of a laserlight ray to label or engrave a material's work surface. The lazer ray is created by the dietary fiber laser beam source and redirected on top of the top of the information simply by using a scanning top of your head. The lazer beam's strength and length are managed by the pc, that may be developed to label a certain layout or creation. The laserlight ray creates a high heat-stricken zone at first of an product, which then causes a change in shade, texture and consistancy, or height, dependant upon the product for being noted. Fiber content laser marking pieces of equipment can create higher than average-quality markings which have beencorrect and sturdy, and lasting.

Fiber content Laser Marking Product Factory Generation Endeavor:

Dietary fibre laser beam marking machine factories result in these appliances in a number of instructions that involve design and development, assembly and fabrication and screening. The design and style endeavor will require setting up a model of an machine as well as ingredients, for instance the fiber laserlight source, checking venture, user interface, and program. Whenever the creation is finished, the production endeavor begins, that requirestwisting and trimming, and welding precious metal pieces to form the machine's body, installing mounting brackets, and other architectural elements.

The construction endeavor will involve positioning every single factors with each other, wiring the electronic circuits, and applying the software program. Once the unit is totally made, it goes through a series of testing to be sure that it fulfills the manufacturer's prime quality guidelines. These tests can include looking at the laser light beam's strength, the scanning head's accuracy and reliability, therefore the software's performance. Whenever the product goes all examinations, it is ready for transport to potential consumers.

Why Fiber content Laserlight Marking Machine Factories are crucial in Today's Construction Arena:

And powerful strategy to tagmerchandise and components, and parts, dietary fiber laserlight marking device factories are very important in today's making business world since they offer aquick and precise. This is especially essential in sectors that demand higher than average-prime quality marks, as an example aerospace,clinical and vehicle, and electronics industries. Fiber laser marking machines can bring about marks which can be proofed against put on, corrosion, and fading, leading them to be great for things that should try to hold up against harsh environments or obtain a much time life span.

Fiber content laser light marking products are undoubtedly kind to the environment as opposed to ancient marking approaches, as an example etching or engraving. They will not use chemical compounds or create risky spend, causing them to be a better and others sustainable approach. Besides that, dietary fiber laser beam marking units tends to be programmed to signature a number of items, integratingplastics and alloys, possibly even cup, rendering them versatile and flexible to several producing techniques.

Summary:

Roughage lazer marking computer industrial facilities carry out a crucial role in today's making arena by supplying higher than average-prime quality equipment that areprecise and proficient, and environmentally friendly. These appliances use cutting-edge lazer modern advances to signature many different elements, giving a swift and effective way to symbolappliances and components, and substances. The production endeavor includes product, production and assemblage and evaluation, making certain that the equipments satisfy the manufacturer's prime quality principles. The flexibility and durability of fiber content laser light marking equipments cause them to become an essential valuable tool in several establishments, causing them to be an important asset for distributors across the world.

Liam Henry

259 Blog posts