Baby chair moulds play a crucial role in producing chairs that are comfortable, durable, and designed with the specific needs and safety of infants and toddlers in mind.

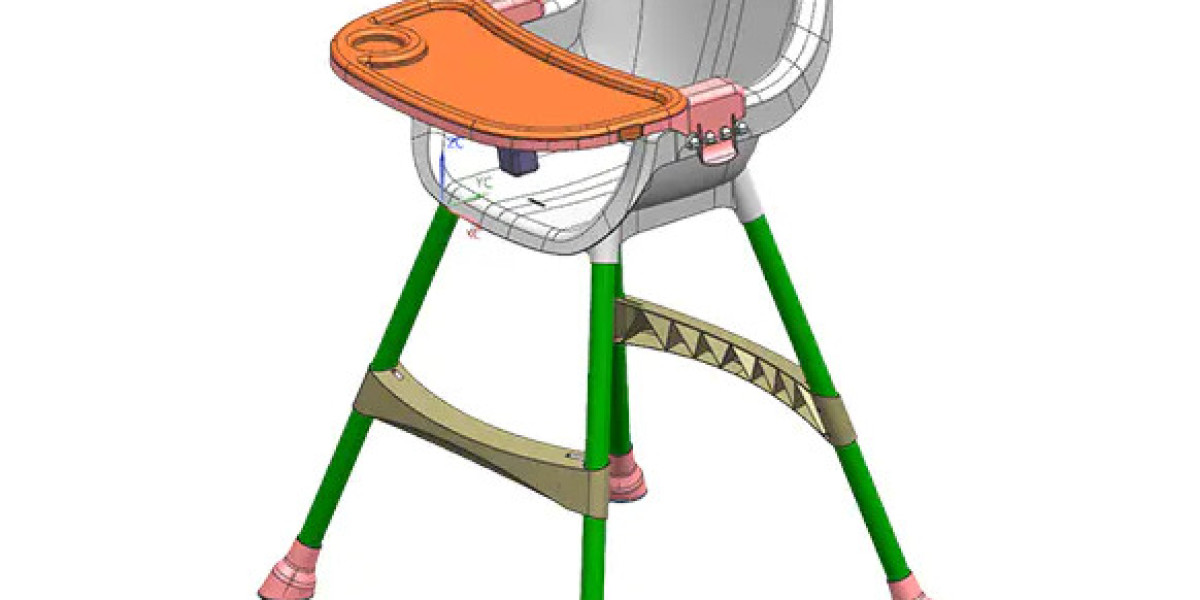

Research and design baby chair mould: The process begins with thorough research to understand the ergonomic and safety requirements of baby chairs. Designers create sketches and 3d models to conceptualize the chair's shape, size, and features.

Material selection: Choosing the right materials is essential for baby chair moulds. High-quality, non-toxic, and durable plastics are commonly used to ensure the safety and longevity of the chairs.

Prototype development: A prototype of the baby chair is created using the baby chair mould to test its design, functionality, and safety features. Prototypes are often subjected to rigorous testing to identify potential improvements.

Safety standards compliance: Baby chair moulds must comply with strict safety standards and regulations to ensure that the chairs are safe for infants and toddlers. This includes testing for stability, strength, and other safety aspects.

Mould fabrication: Once the design baby chair mould is finalized and tested, the actual baby chair mould is fabricated. The baby chair mould is precision-engineered to produce consistent and accurate chair parts.

Injection moulding: Baby chair mould is used in the injection moulding process, where molten plastic is injected into baby chair mould cavity to form the chair's components. This process allows for efficient and high-volume production.

Quality control: Throughout the production process, quality control measures are implemented to ensure that each chair meets the desired specifications and safety standards.

Assembly and finishing: After the chair components are moulded, they are assembled, and any necessary finishing touches are added, such as cushioning or decorative elements.

Testing and certification: The finished baby chairs are tested again to verify their safety and functionality. They may undergo additional certifications to meet international safety standards.

Packaging and distribution: The baby chairs are packaged for distribution, and they are ready to reach homes, nurseries, and stores worldwide.

Feedback and continuous improvement: Manufacturers gather feedback from customers and continue to improve the design and functionality of the baby chair moulds based on real-world usage and experiences.

Baby chair mould manufacturers creating baby chair moulds is a delicate and detail-oriented process that demands a commitment to safety, comfort, and style. The goal is to produce chairs that nurture the comfort of little ones while providing parents and caregivers with peace of mind in knowing that their babies are seated securely and comfortably.